Semilab publishes study on “Femtosecond laser darkened copper surfaces: Characterization for possible application as laser beam blocker”

07.19.2024

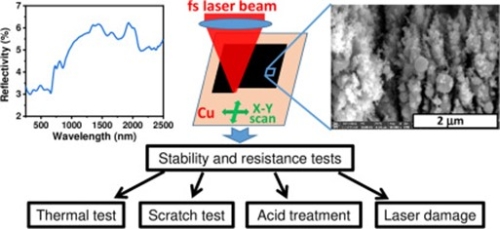

Semilab publishes study focusing on the optical and mechanical properties of copper surfaces darkened by femtosecond laser irradiation, regarding their applicability as laser beam blockers.

Laser processing of metal surfaces has been a well-known and increasingly popular technique for various applications, including surface modification and material removal. One of the key outcomes of laser processing of metals is surface nanostructuring, which can induce a decrease the reflectivity over a wide wavelength range from ultraviolet to near-infrared. Copper is widely used in various industries due to its good conductivity and thermal properties. However, its surface features, such as reflectivity, wetting behavior, and resistance to various environmental factors, can limit its applications in some cases. To overcome these limitations, several surface modification techniques have been developed, including laser processing, which is a promising method. Earlier studies already reported that laser surface nanostructuring can alter the mechanical, optical, electrical, and biological properties of copper samples, while other studies have focused on how laser processing affects the surface roughness and wettability of copper.

These earlier published papers have demonstrated the potential of laser surface nanostructuring as a powerful tool for modifying the surface properties of copper and other materials. However, other promising features and applications of the blackened surfaces remained unclear.

The goal of this study was motivated by the quest for possible practical uses of darkened copper surfaces, especially in the field of laser systems. For high-energy lasers, it is essential that the material and design of the beam blocker should minimize reflection and scatter to avoid damage to surrounding equipment or personnel. High-energy laser beam blockers often include cooling systems such as heat sinks or even active cooling systems (e.g. water), as the generated heat can rapidly warm up the blocker; if the heat is not efficiently dissipated, the blocker could overheat and fail, posing a risk to the laser system and the environment. For this reason, beam blockers for high-energy laser pulses are relatively large and complex in design to avoid scattering.

To learn more about the results and our experts’ findings regarding the nanostructure of the blackened copper plates, keep reading HERE.