How to Determine the Internal Wettability of Nanostructured Thin Films

08.24.2023

Thin film technology is ubiquitous in modern society. It is the bedrock for countless devices, including displays, transistors, waveguides, and more. Materials scientists continue to push the boundaries of possibility through thin film engineering. Nanostructuring is one approach to this.

Nanostructured thin films are unique in the realm of nanotech. They may be several micrometers thick. Yet, they feature high concentrations of structures with nanoscale dimensions (dislocations, grain boundaries, etc.). This imparts superior mechanical properties to bulk materials of the same composition. One example is wettability.

This article delves deep into the intricacies of determining the wettability of nanostructured thin films, emphasizing the significance of spectral ellipsometry and ellipsometric porosimetry.

The Importance of Wettability in Thin Films

Wettability is a crucial parameter when it comes to nanostructured surfaces. It plays a vital role in the performance of antireflective coatings, self-cleaning mechanisms, smart windows, gas-sensing devices, and membranes. While determining contact angle (θ) on planar surfaces is a routine task, it doesn't necessarily translate to the intrinsic wetting behavior of nanostructured materials.

Ellipsometric Porosimetry: A Powerful Characterization Technique

Semilab ellipsometric porosimetry (PS-2000) is a leading characterization technique for mesoporous thin films. It offers a comprehensive insight into the porosity, pore size, specific surface area, and Young's modulus of thin film mono- and multilayers. This method is purely optical and non-destructive, ensuring the sample's integrity remains uncompromised.

Ellipsometric porosimetry (EP) measures the change in a thin film's optical properties. This change is induced by the adsorption or desorption of solvent vapor in the pores. By doing so, EP extracts a series of film thicknesses and refractive indices, providing a detailed profile of the film's characteristics.

Investigating Internal Wettability

A recent study focused on the internal wettability of functionalized silica materials using ellipsometric porosimetry. The findings revealed that methyl-functionalization of the silica surface led to delayed capillary condensation in the volume-adsorbed isotherms. This effect was particularly pronounced with the two more polar adsorptives. By comparing non-functionalized and functionalized silica surfaces, it became feasible to calculate internal contact angle values for all the tested liquids.

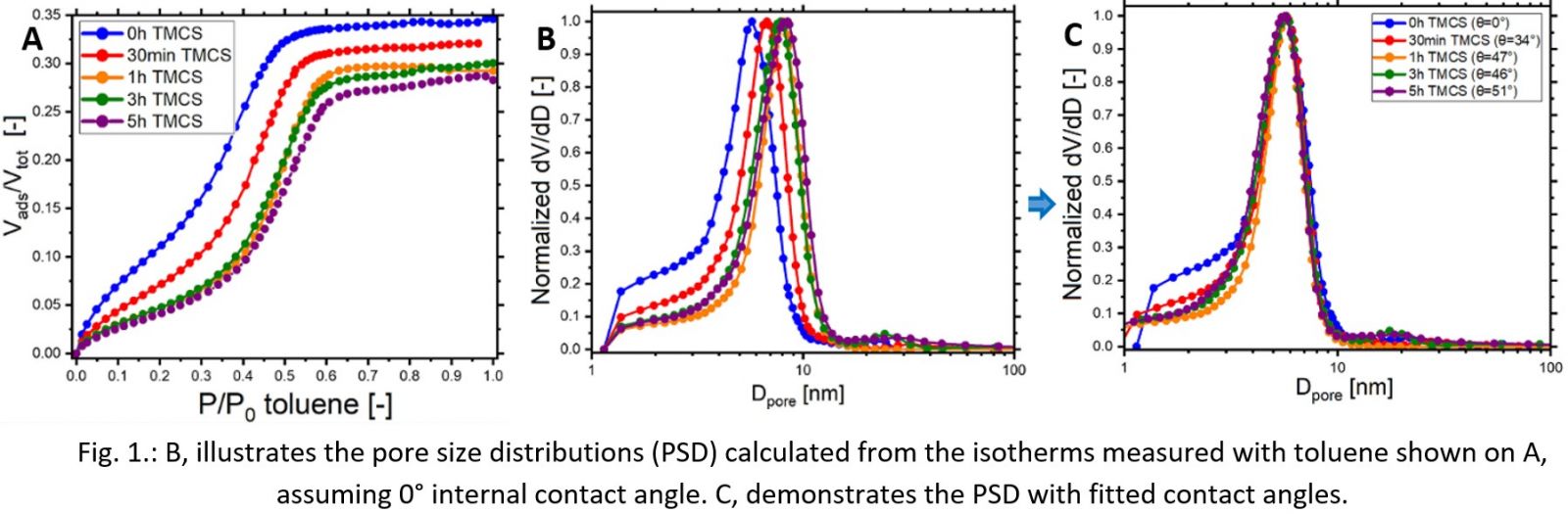

The results, depicted in Fig. 1, clearly showcase surface energy's influence and adsorbate polarity's effect on the internal contact angles.

Applications in Various Materials

The principles of wettability in nanostructured thin films are not limited to a single material. They find relevance in various porous thin films, including SiO2, TiO2, ZnO, and WO3. Furthermore, nanoparticles, low k-, mesoporous, and microporous materials also benefit from these insights, paving the way for advancements in materials science.

Understanding the wettability of nanostructured thin films is just one of many challenges in materials science. But it is a critical one. With tools like spectral ellipsometry and ellipsometric porosimetry, we at Semilab are at the forefront of this exploration. Our PS-2000 is a testament to our commitment to providing the best characterization techniques for mesoporous thin films.

For those keen on diving deeper into the world of thin films and their myriad applications, we invite you to explore the capabilities of PS-2000. Together, let's shape the future of materials science.

You can read our publication on this topic: Máté Füredi et al., “Internal wettability investigation of mesoporous silica by ellipsometric porosimetry” in Science Direct Volume 768, 1 March 2023, doi: 10.1016/j.tsf.2023.139683.