Application

ION IMPLANT MONITORING

Modern semiconductor devices require precisely controlled dopant concentration and position, and this can be achieved by ion implanting with careful annealing. Typically an n-type species is implanted into a p-type material, or the other way around. Typical species to implant can be boron and indium for the p-type, phosphorus, arsenic and antimony for the n-type layer. Implants are monitored by adding a monitor wafer, and the monitor wafers are checked after the implantation and annealing. Alternatively, the monitoring can be performed by using test boxes on product wafers.

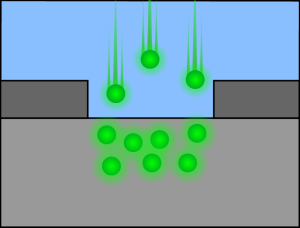

Figure 1. Implantation

Figure 1. Implantation