Application

PARALLEL DIPOLE LINE HALL MEASUREMENT

| The PDL Hall system is capable of both AC and DC Hall measurement modes. The AC field measurement can be used for materials with the mobility of below 0.1 cm2/Vs, which is an advantage compared to the DC field measurement mode. Materials with such attributes are usually semiconductor, photovoltaic or thermoelectric materials. |  |

Technology

HIGH-SENSIVITY PARALLEL DIPOLE LINE (PDL) HALL MEASUREMENT

Hall measurement is one of the most important measurement for electronic materials & devices. However Hall measurement of low mobility, very thin film (very high resistance) or very low resistance (e.g.: metal) is problematic or impossible due to very low signal to noise (S/N) ratio.

What could solve this research problem?

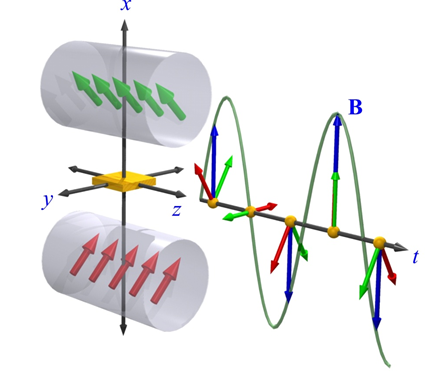

If you generate alternating (ac) magnetic field and perfom lock-in detection.

For this the parallel dipole line (PDL) system presents a novel magnetic trap system that demonstrates a unique “camelback field confinement” effect. It traps a diamagnetic object (e.g. graphite) at the center due to diamagnetic levitation effect.

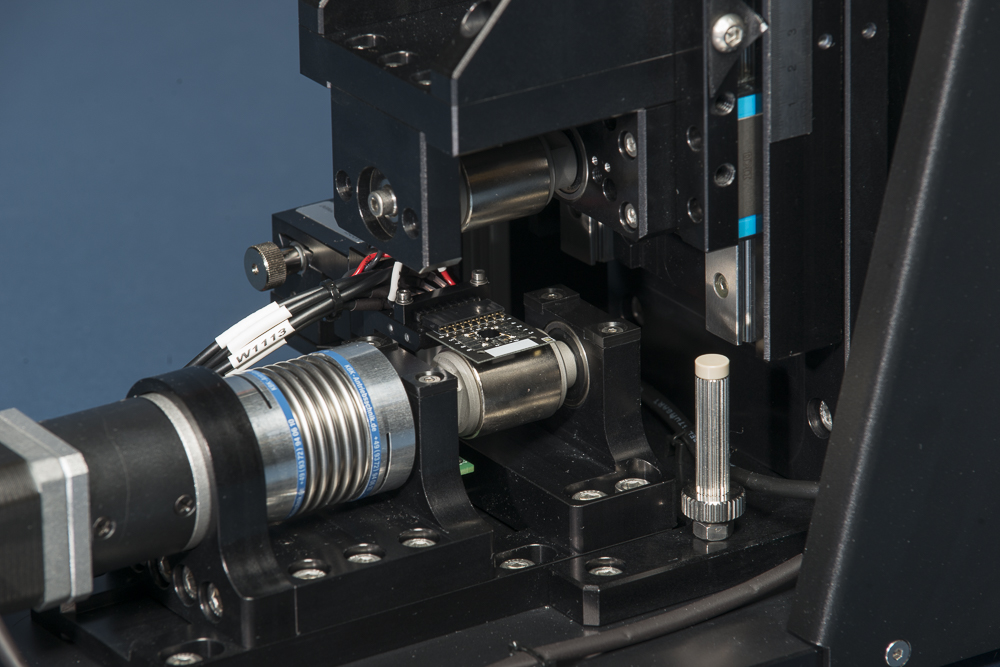

By using such technology Semilab Parallel Dipole Line Hall Measurement System (PDL-1000) is able to measure sheet resistance, carrier concentration and mobility in wide ranges, with high sensitivity for R&D application.

The PDL Hall effect technique offered in the SEMILAB PDL-1000 system has been developed and patented by IBM.

Read here more about the IBM research of PDL Hall effect technique.

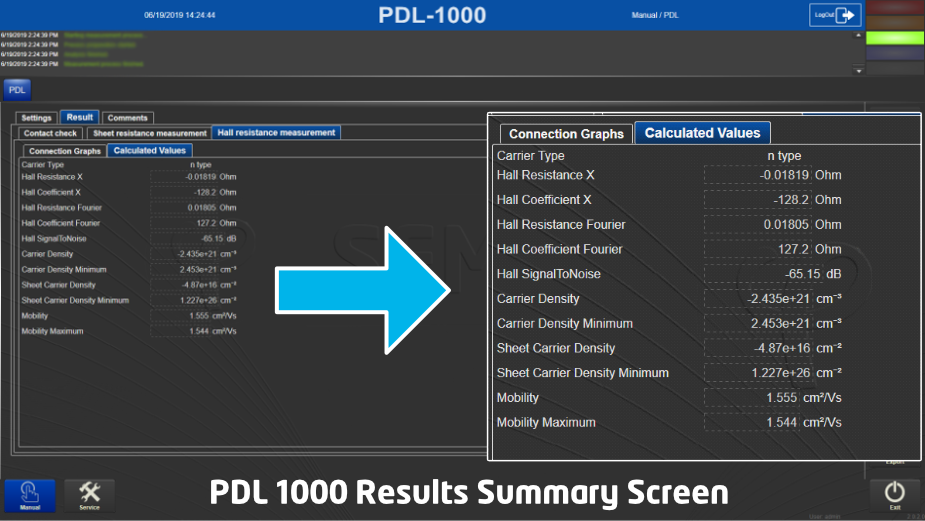

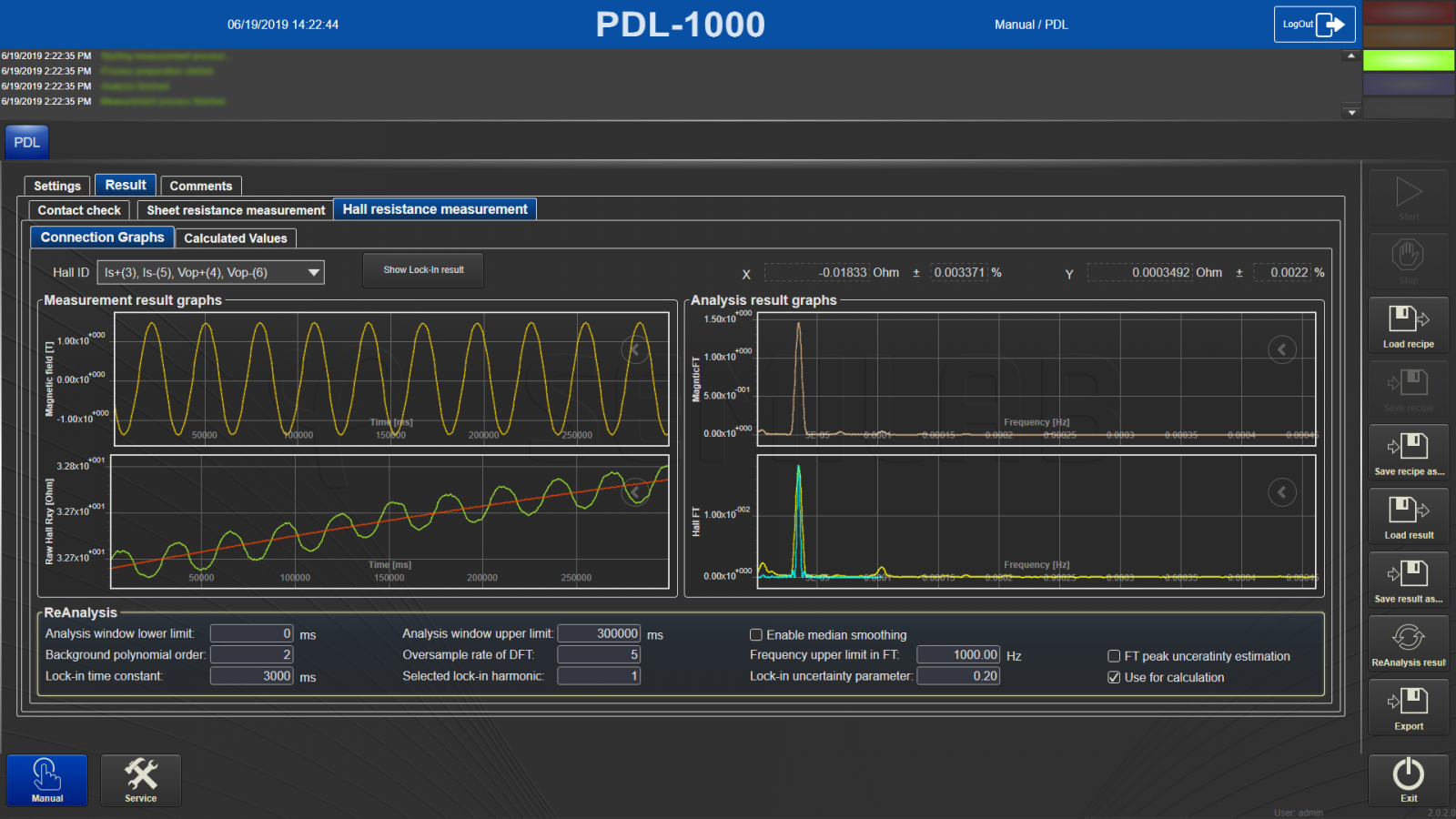

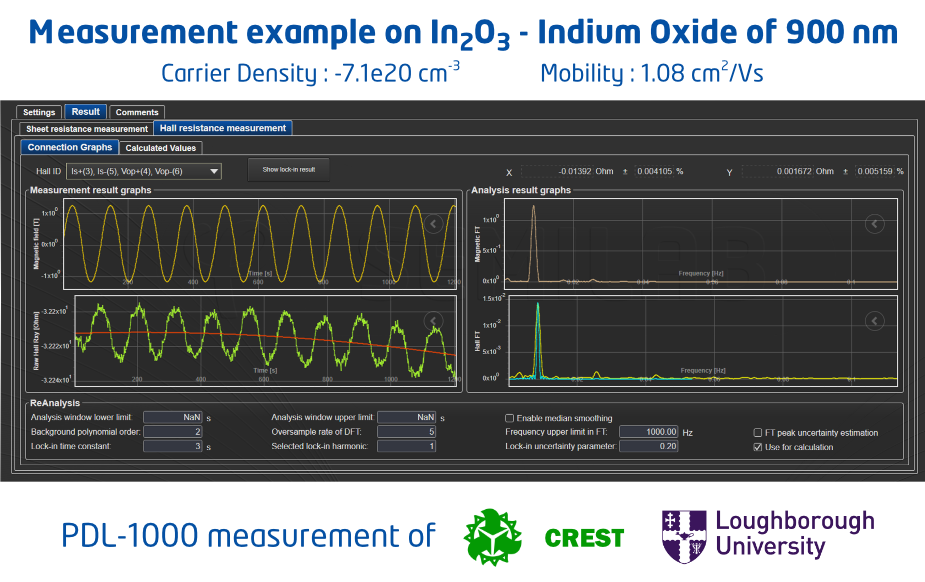

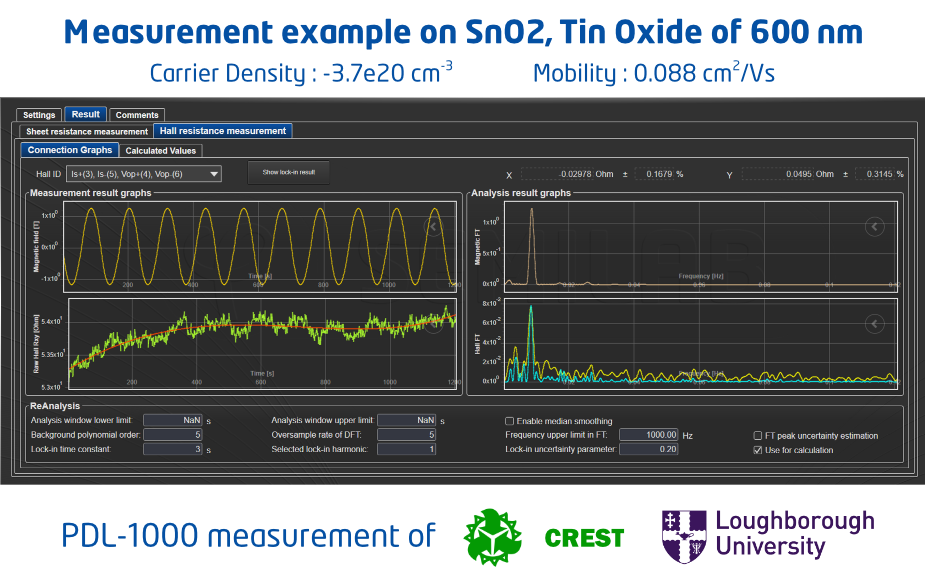

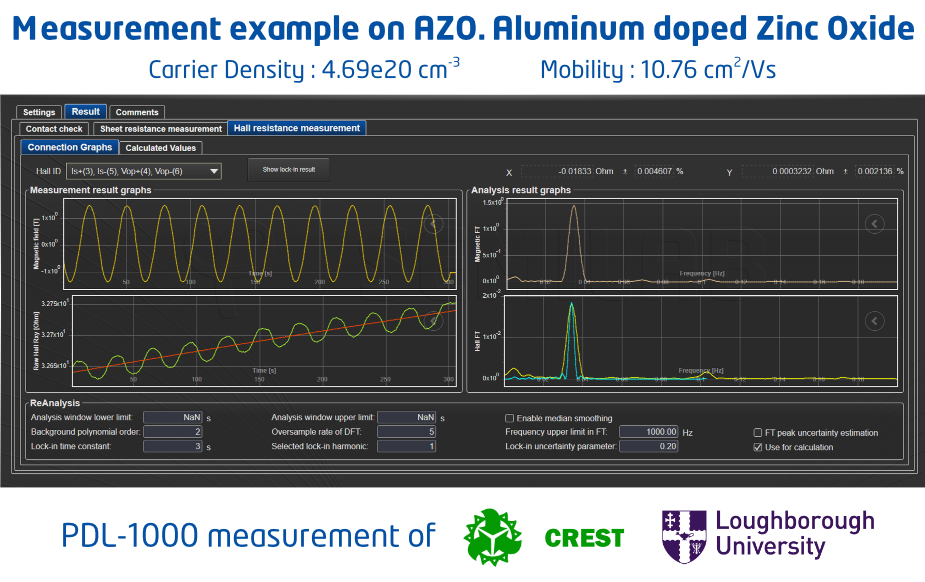

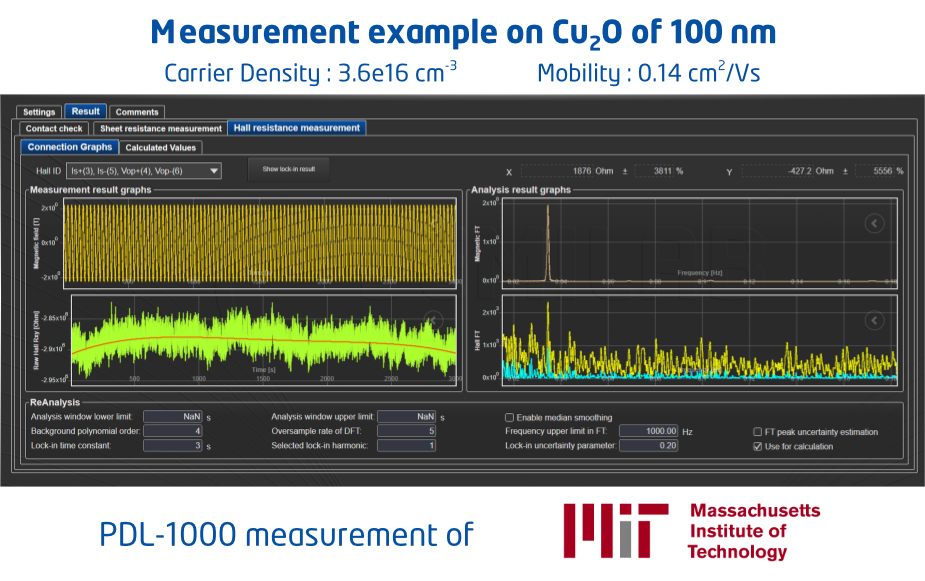

PDL-1000 measurement results are presented in a user-friendly way:

|

|

|

FEATURES

- Ability to measure a wide range of mobilities, including extremely low mobilities and semi-insulating samples. Includes capability to perform both alternating (AC) and traditional static field (DC) Hall measurements.

- Software extracts low Hall signal using software-based lock-in detection (eliminating the need for costly hardware-based lock-in detection)

- Tabletop setup,

- Utilizing rotating Parallel Dipole Line magnets (no bulky electromagnet required)

- The rotating PDL system can serve as basic building block to generate AC field for various experiment or test systems (General purpose AC magnetic field system, Faraday effect, Photoelectromagnet (PEM) effect)

Product Line

PDL

Semilab Parallel Dipole Line Hall Measurement System is a standalone device for measurement of sheet resistance, carrier concentration and mobility.

PDL system uses AC and DC field Hall measurement methods with permanent magnets, fully integrated instrumentation and software for enhanced research productivity.

Semilab PDL Hall system is capable of measuring several materials, like semiconductors, compound materials (III-V, II-VI), solar cells, transparent conductive oxides (TCOs) and organics electronics (OTFT, OLED) with very high sensitivity.

|

|

|

|

Products

PDL-1000

- High sensitivity (able to handle mobility less than 0.1 cm2/Vs)

- Large magnetic field (approximately 2,5 T pk-pk)

- Uniformity (< 2% sample size up to 10×10 mm)

- Proprietary signal processing and user interface (UI) software

- Software-controlled measurement and automated parameter extraction

- Compact tabletop system design

- User-friendly operation

- Gate bias voltage option

- No cooling system necessary