Application

DIELECTRIC POROSITY MEASUREMENT

Porous films in microelectronics

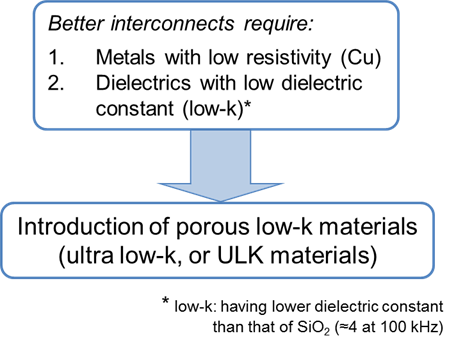

- For decreasing the capacitance of interconnection isolators in integrated circuits:

- Decrease of RC time delay (increase of operating frequency)

- Decrease of power consumption

- For further decreasing the dielectric constant, the material has to be porous

- This implies additional reliability questions, eg.:

- Cracking / adsorption loss (need to stay on the substrate for long)

- Mechanical strength (need to survive chemical-mechanical polishing, CMP)

- Typical Young modulus of SiO2 is 70 GPa (for dense SiOCH: <15 GPa, for porous SiOCH: <10 GPa)

- Moisture absorption (need to be hydrophobic, in order to remain a good insulator)

- Dielectric constant depend on porosity, eg. for porous SiOCH*:

- ULK (ultra low-k): k ≈ 2.5 , with porosity ≈ 20% and pore size ≈ 3-4 nm

- ELK (extreme low-k): k ≈ 2.3, with porosity ≈ 30% and pore size ≈ 5-6 nm

- This implies additional reliability questions, eg.:

- Characterization of porous dielectric layers is necessary to ensure reliable layer fabrication