Application

SI WAFER SORTING

Sorter applications provide advanced multiparameter wafer inspection with integrated high speed sorting for quality control of production PV wafers. Owing to wide range automation module portfolio and flexible combined Semilab’s metrology modules, all customer can find perfect configuration what fulfil their production expectations.

Application area:

- Outgoing wafer inspection for wafer manufacturers

- Incoming as-cut wafer inspection for solar cell manufacturers

Sorter purpose

- Eliminating damaged wafers from further process

- Eliminating high thickness variation wafers (TTV, saw mark)

- Sorting of potentially weak wafers (microcracks) which could break in subsequent process steps

- Sorting based on resistivity, and lifetime values

- Sorting of wafers with dislocations, high contamination and vacancy density

- Wafer input: loading from cassettes or stack

- Wafer output: Sorting in different user-defined classes, collection in coin stacks

- High throughput

Technology

MICROCRACK INSPECTION

MicroCrack Inspection (MCI) System detects internal material defects – inline and in tact time. It helps our customers optimizing the production yield to further decrease the costs/Wp.

Micro-Cracks:

- Can happen anywhere in the process

- Can cause breakage of wafers or cells in the production line

- Can influence the electrical performance of the final processed cell

Material-Inclusion:

- Can impact the electrical efficiency of the final processed cells.

Holes:

- Appear mostly in conjunction with material inclusions

- Can cause shunts and therefore influence the electrical performance of the final processed cell

- Can cause breakage due to lower wafer stability

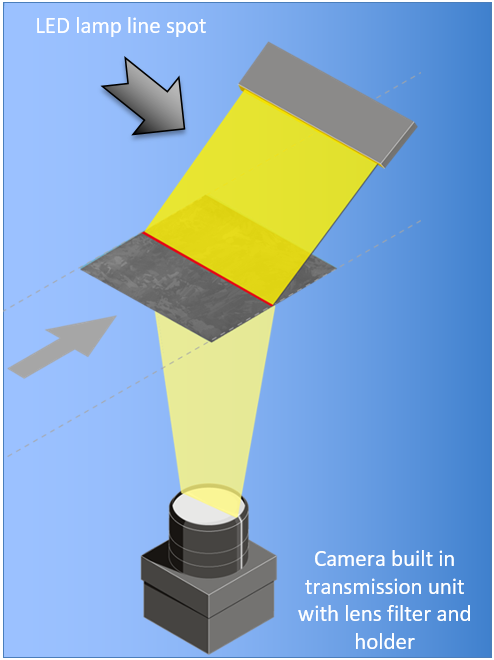

Theory of MCI (transmission) imaging: On-the-fly process where the wafer passes through between the line 4K camera and the IR range (LED) line illumination. At first image processing software searches the edges of the wafer. Secondly searches the suspicious defects in the image. Suspicious areas are further investigated and classified according to the configured parameters. Individual inspection parameter sets can be configured and loaded for each type of wafer.

Inspected defects:

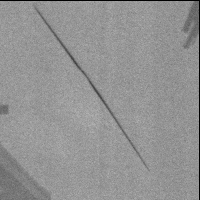

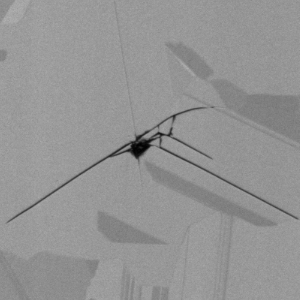

- Micro-crack – Micro-cracks in MCI image:

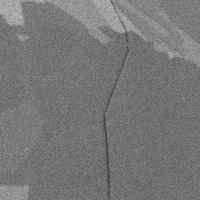

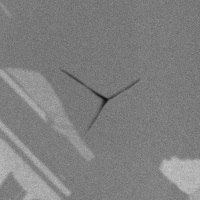

- Inclusions - Small material inclusions in MCI image:

- Pinholes – Holes in MCI image:

FEATURES

- Minimize breakage rate, which results lower costs

- Minimize bad material, which results higher efficiency

- Avoid subsequent breakage of flawless wafers

- Reduce down time

- Save on process costs

- Provide reason for complaints

Product Line

PVS

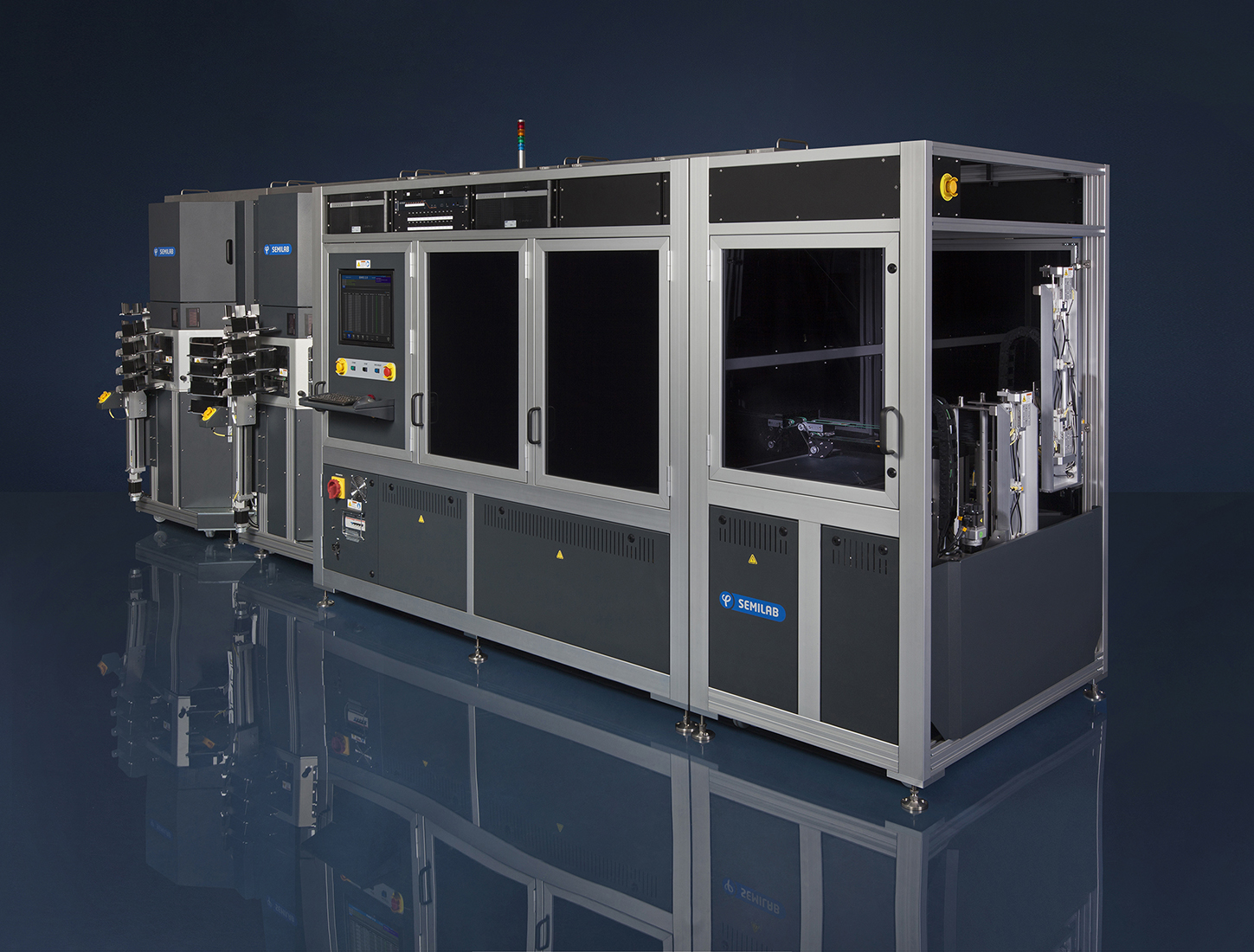

The PVS product line provides advanced multi-parameter wafer inspection with integrated high speed sorting for quality control of production wafers. It eliminates imperfect substrates, maximize cell line output and ensures optimized efficiency.

It combines high reliability wafer handling with Semilab’s industry leading PV metrology, to provide a turnkey solution for sorting of incoming wafers. This is backed by direct expert support from the OEM metrology manufacturer, through our worldwide network of branch offices.

Products

PVS-5000

PVS-5000 is a high throughput, field proven PV Wafer Inspection and Sorting System.

It combines high reliability wafer handling with Semilab’s industry leading PV metrology, to provide a turnkey solution for sorting of incoming wafers. This is backed by direct expert support from the OEM metrology manufacturer, through our worldwide network of branch offices.

Loaders

- PVLS-5400 Automated stack loader with 3 position pick-and-place system. Up to 2400 pcs buffered wafer in 12 pcs carrier.

- PVLC-3600* Automated cassette loaders for 25/50/100 slot cassettes

- PVLC-3600-AL Fully automated production line loader for 100 slot cassettes

Metrologies

- PLI-101/3 Photoluminescence imaging

- WML-1 Minority carrier lifetime measurement

- SHP-200 2D measurement

- MCI-150 Micro crack inspection

- WSI-120 Surface chipping and contamination inspection

- TTR-300 Thickness, resistivity measurement

- TTR-300 Saw mark Inspection

Unloaders

- PVULS-5406T High speed stack unloader with 6 bin

- PVULS-5407T High speed multilevel stack unloader with 7 bin

PVS-6000

PVS-6000 is a High Speed, field proven PV Wafer Inspection and Sorting System with 5400 wafer per hour throughput. It combines high reliability wafer handling with Semilab’s industry leading PV metrology, to provide a turnkey solution for sorting of incoming wafers. This is backed by direct expert support from the OEM metrology manufacturer, through our worldwide network of branch offices.

Loaders:

- PVLS-5400 Automated stack loader with 3 position pick-and-place system. Up to 2400 pcs buffered wafer in 12 pcs carrier.

- PVLC-3600 Automated cassette loaders for 25/50/100 slot cassettes

- PVLC-3600-AL Fully automated production line loader for 100 slot cassettes

Metrologies:

- PLI-101/3 Photoluminescence imaging

- WML-1 Minority carrier lifetime measurement

- SHP-200 2D measurement

- MCI-150 Micro crack inspection

- WSI-120 Surface chipping and contamination inspection

- TTR-300 Thickness, resistivity measurement

- TTR-300 Sawmark Inspection

Unloaders:

- PVULS-5406T High speed stack unloader with 6 bin

- PVULS-5407T High speed multilevel stack unloader with 7 bin