Application

INLINE PROCESS CONTROL

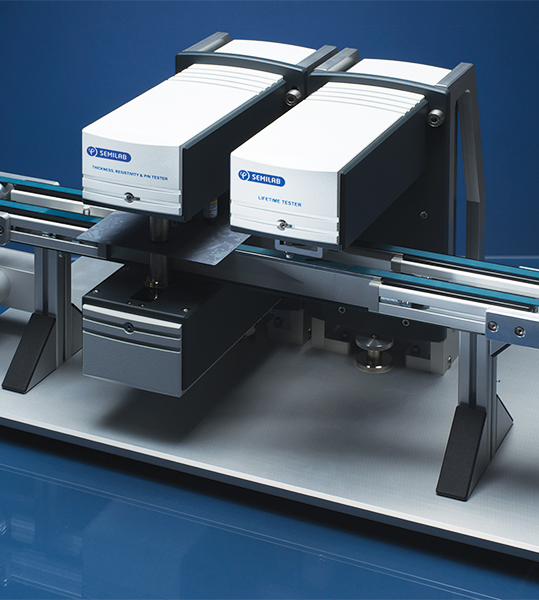

Besides Semilab’s own automated wafer sorter platform, Semilab manufactures separate measurement units for integration into automated PV production lines. Semilab has been working together with all the relevant automation companies to integrate the measurement units.

The equipments cover a diverse range of metrology needs for comprehensive process and quality control in Si PV industry:

- Incoming wafer inspection and process control during cell manufacturing

- Measurement in as-cut wafer, textured, after diffusion, after passivation, after ARC deposition, after contact formation states

- Measurements of geometrical, electrical and optical properties

- Solutions for mono and multicrystalline silicon materials, Al-BSF, PERC, IBC and heterojunction cell concepts

All measurement units are designed considering the following directives:

- Compatibility to state-of-the-art production lines

- Supporting all the industry standard communication protocols

- Flexible integration

- Supporting both „on-the-fly” and „stop-and-go” data acquisition modes

- Compact design

- Simple integration and support

- Simple maintenance, rare calibration periods

- Application of noise reduction solutions

- Simple and configurable customization of communication protocols

Technology

SPECTROSCOPIC ELLIPSOMETRY

In the semiconductor industry, there is continuous demand for higher performance and denser integrated circuits. These requirements push the advancement of technology which requires solving of manufacturing challenges. A key to success is to understand the chemical, mechanical and physical properties of wide range of materials used in a typical integrated circuit.

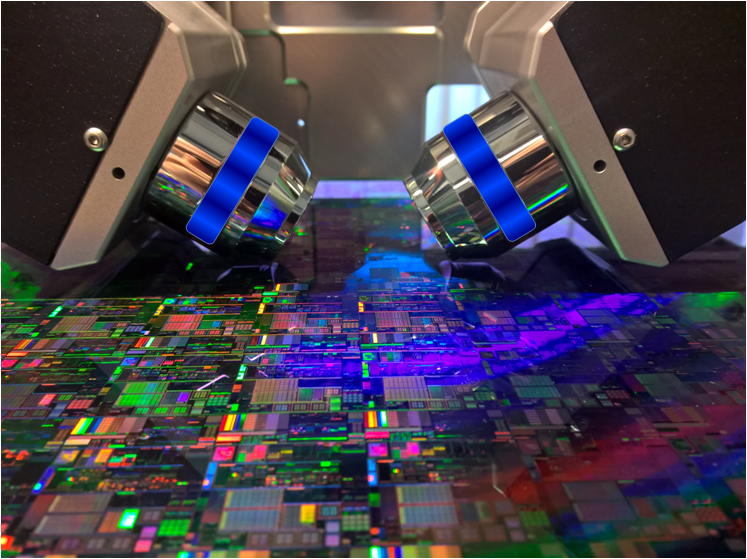

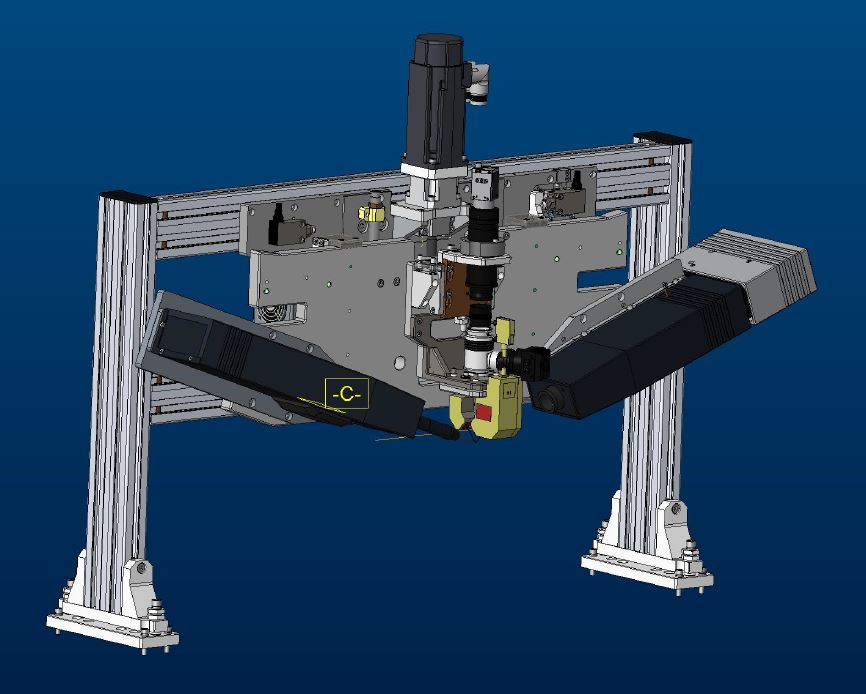

The µSE tool is designed to measure thin film thickness and optical properties inside a <50µm test pad on semiconductor product wafers. The applied measurement technique for obtaining these parameters in a high accuracy and repeatable way is spectroscopic ellipsometry. The μSE tool uses optimized spectroscopic ellipsometer (SE) arms and optics for the measurement inside small boxes of patterned Si wafers.

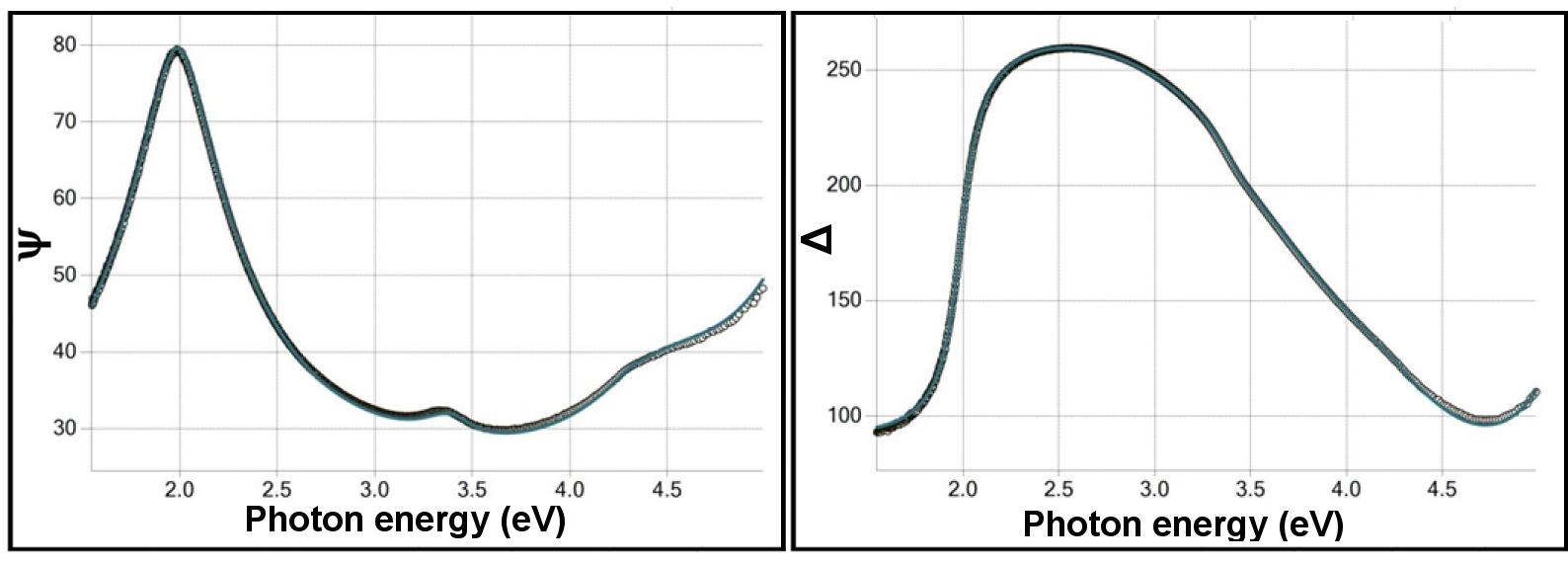

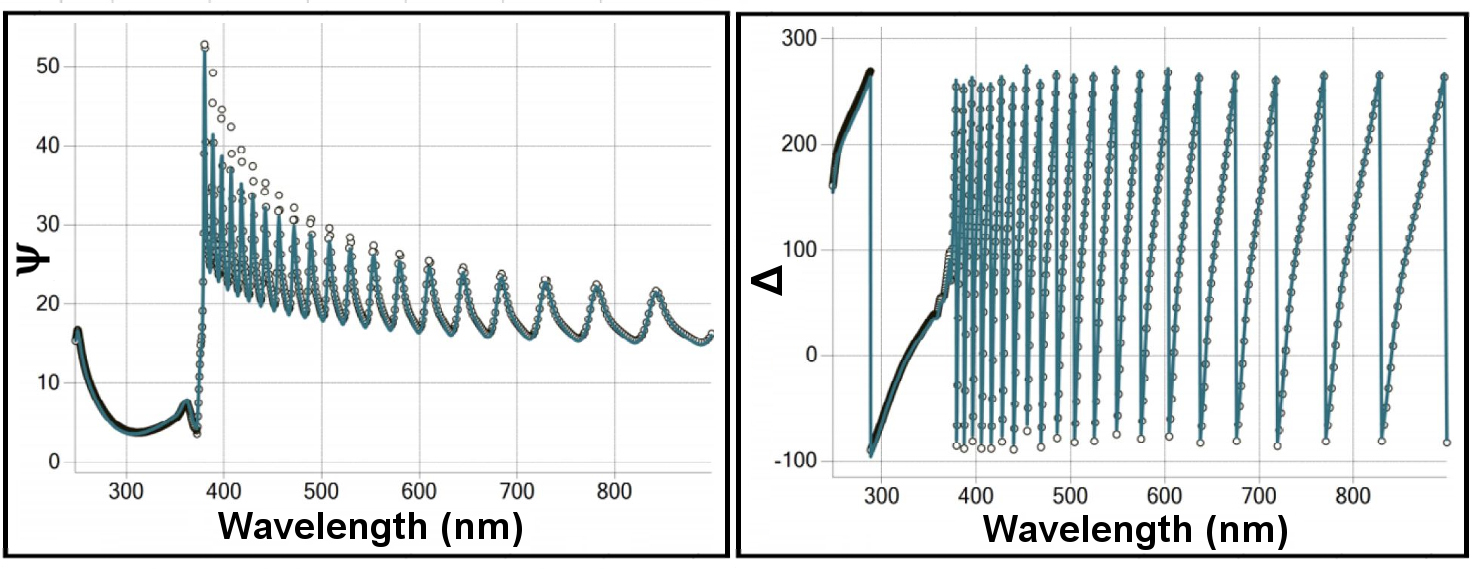

Ellipsometry measures the phase of the reflected light from the sample, therefore it is relatively insensitive for intensity fluctuations. The raw measurement data represent the complex information from the layer stack which then need to be modeled optically. The measurement results are obtained through numerical regression process of the model data to the raw measurement spectrum.

TYPICAL SE REGRESSIONS:

FEATURES

- Non-destructive optical technique, based on measurement of the change of the polarisation state of light after reflection at non normal incidence on the surface to study.

- It is a higly sensitive even for layer thickness below 5 nm

- Extremely versatile technique: it gives acccess to numerous parameters which characterize multilayer structures (eg. layer thickness, refractive index, absorption, porosity).

Product Line

SE

Refractive optical design in compact realization: short optical path inside the measurement arms (reduced alignment artifact errors). Active temperature control: stabilized environment for system reli-ability enhancement. Uniqe patented high brightness light source for outstanding SNR. CCD detector array (spectrum is taken simultaneously at different wavelengths).