Application

INLINE PROCESS CONTROL

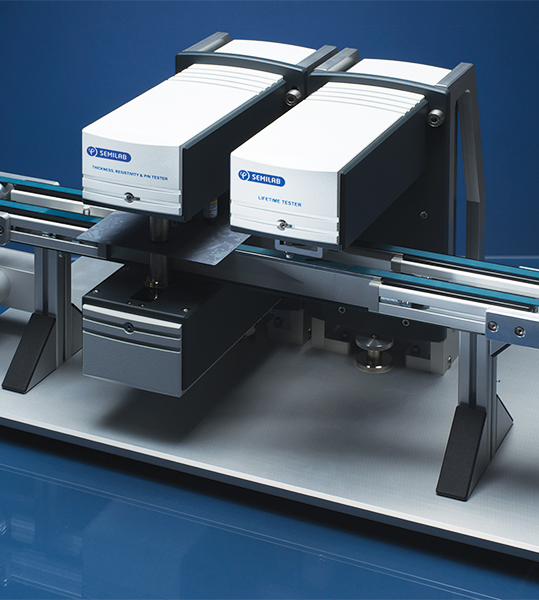

Besides Semilab’s own automated wafer sorter platform, Semilab manufactures separate measurement units for integration into automated PV production lines. Semilab has been working together with all the relevant automation companies to integrate the measurement units.

The equipments cover a diverse range of metrology needs for comprehensive process and quality control in Si PV industry:

- Incoming wafer inspection and process control during cell manufacturing

- Measurement in as-cut wafer, textured, after diffusion, after passivation, after ARC deposition, after contact formation states

- Measurements of geometrical, electrical and optical properties

- Solutions for mono and multicrystalline silicon materials, Al-BSF, PERC, IBC and heterojunction cell concepts

All measurement units are designed considering the following directives:

- Compatibility to state-of-the-art production lines

- Supporting all the industry standard communication protocols

- Flexible integration

- Supporting both „on-the-fly” and „stop-and-go” data acquisition modes

- Compact design

- Simple integration and support

- Simple maintenance, rare calibration periods

- Application of noise reduction solutions

- Simple and configurable customization of communication protocols

Technology

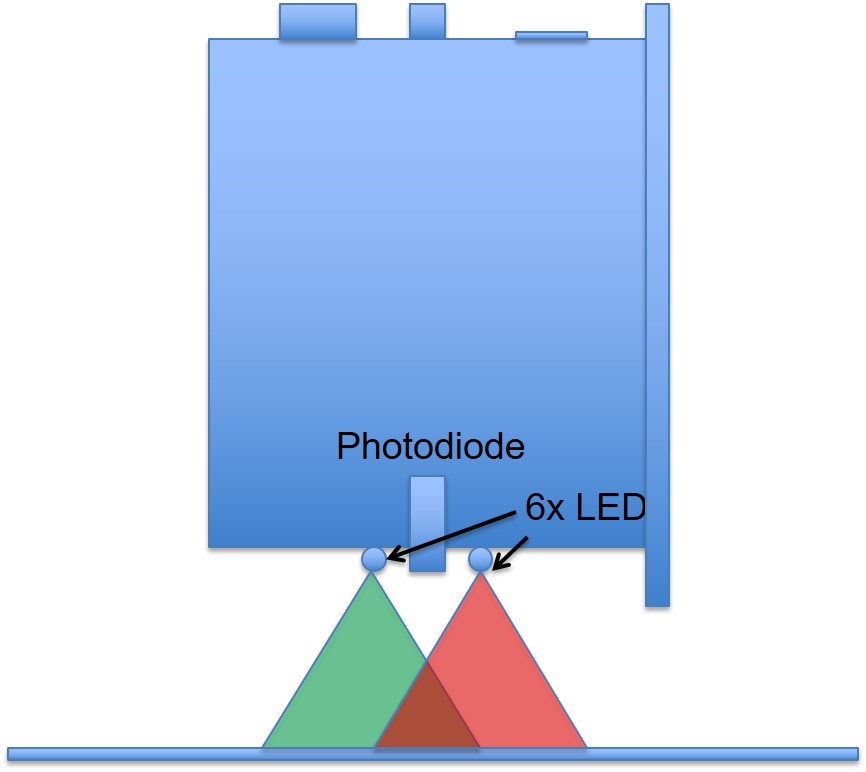

COLOR MEASUREMENT FOR CELLS

Color Inspection tool with discrete wavelenghts is a powerful and fast method for sorting cells into 3-5 groups based on visual color to make uniform color modules. The idea is to use discrete wavelengths and have multiple linescans across the cell. This configuration has the possibility to individually tune the different wavelengths for optimum performance.

Up to 6 heads can be put over one 156mm wafer.

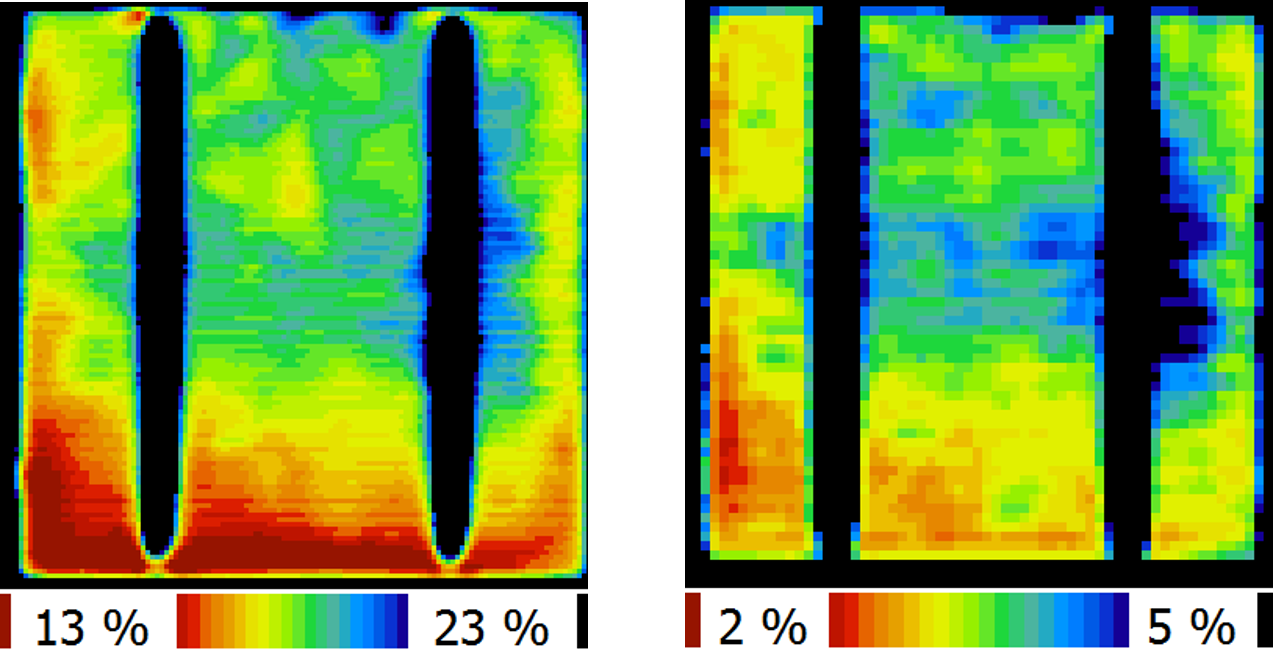

Reflection maps with preliminary single WL head:

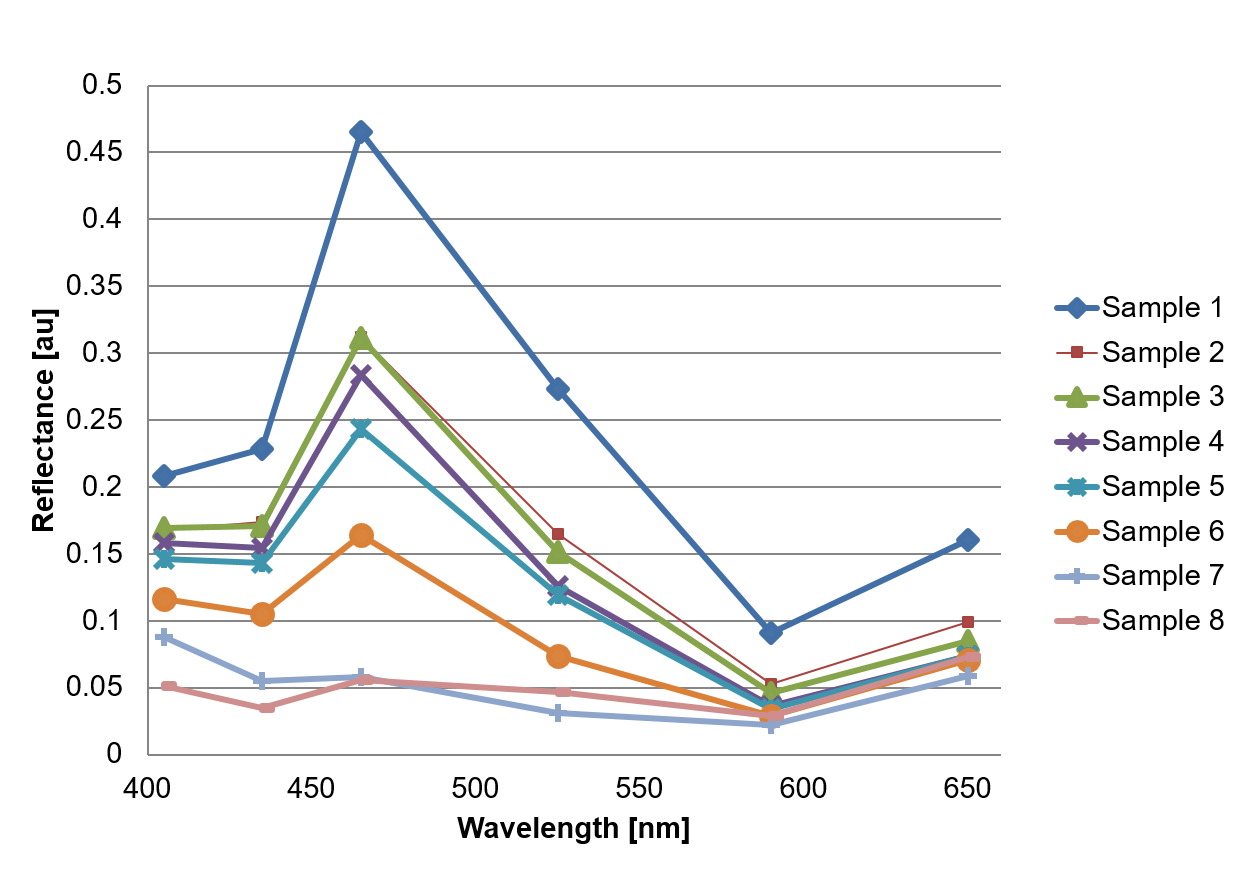

Results on test samples:

Sample 1

Sample 2

Sample 3

Sample 4

Sample 5

Sample 6

Sample 7

Sample 8

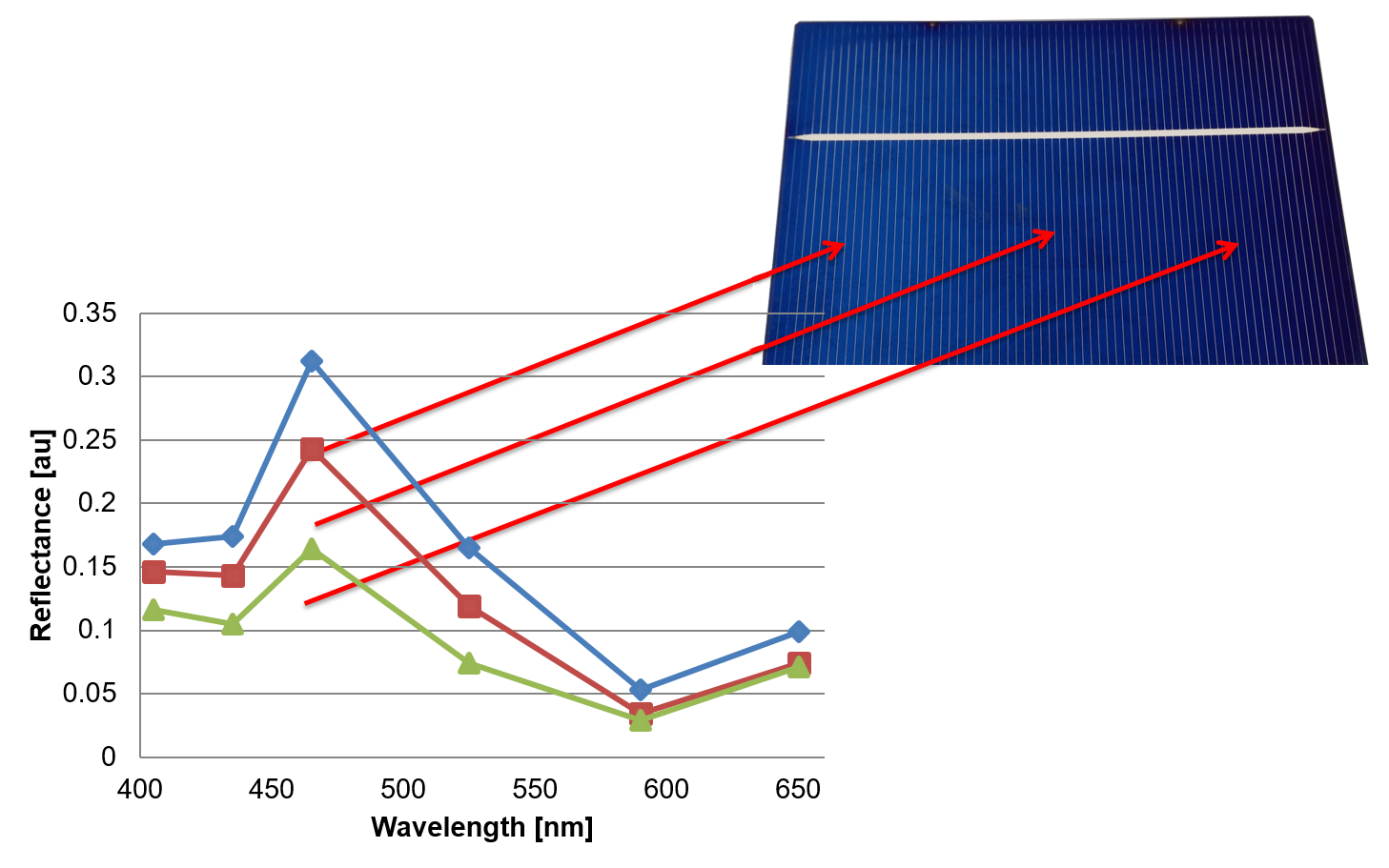

Results on Semilab test samples:

Results on one sample with high inhomogeneity:

FEATURES

- Simultaneous measurement of the 6 heads

- Adjustable number of heads and the positions

- Possibility to mount to the standard in-line tool holder

- Built in temperature measurement for better stability

- Diffuser and mirror for better homogeneity and higher signal

- Built in router for less cabling

- Better cooling

Product Line

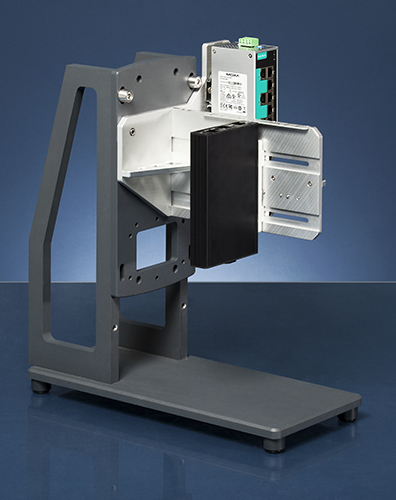

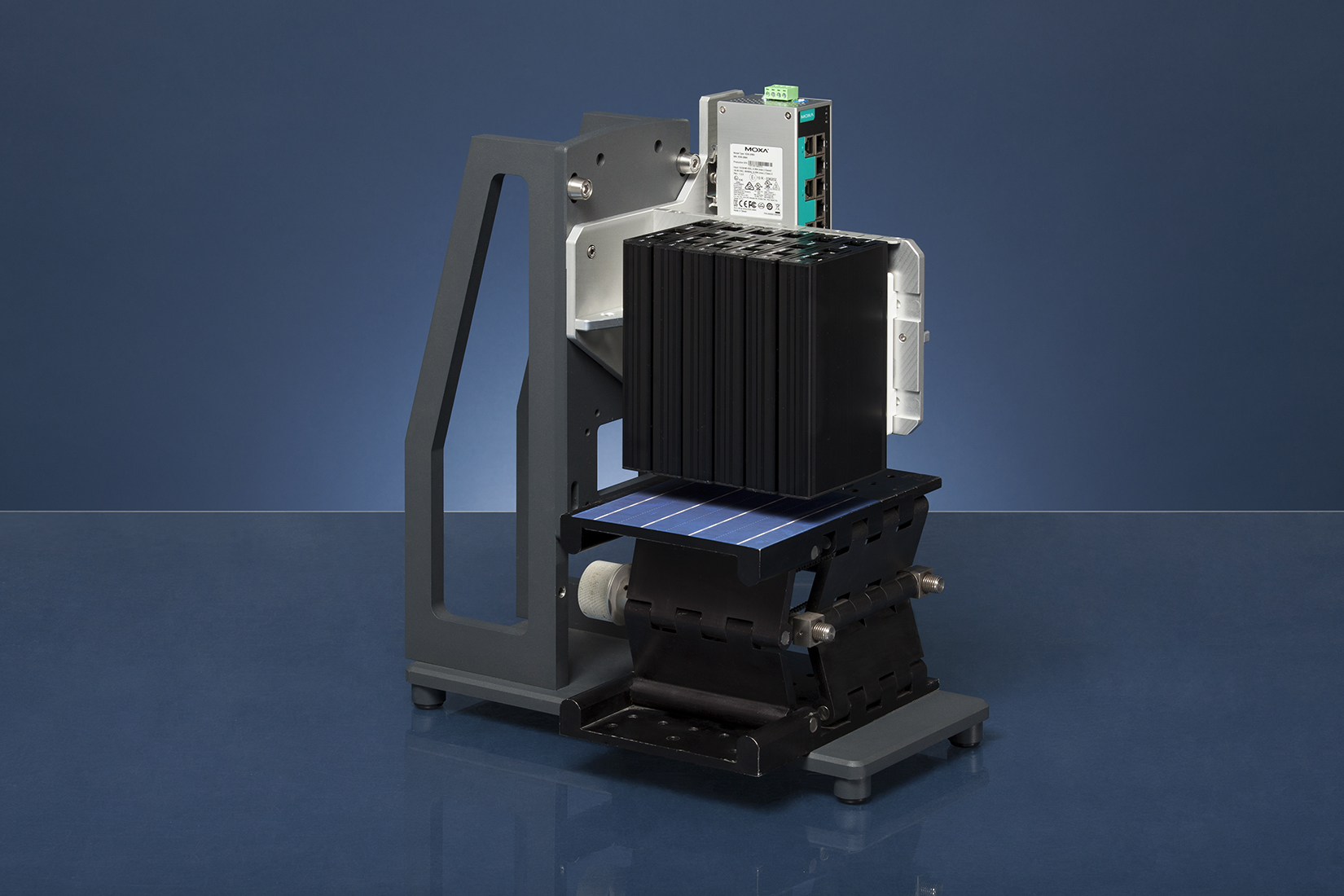

SCI

SCI inline tools provide non-contact, preparation free, high-speed color measurement of wafers after ARC deposition and solar cells. The robust design and the simple integration make it an optimal choice for industrial level sorting of different color wafers and cells, even for the upgrade of existing production lines. Reflected photons at six wavelengths are captured parallel in the same time, and results excellent sensitivity to reflection changes over the whole range of interest, especially in the blue color range.

The modular SCI platform makes possible the simple and flexible integration and positioning of any number of the measurement heads up to 6. The 6 sensors setup is designed to acquire information from the total area of the 156mm x156mm cells.

The SCI measuring equipment is designed for industrial on-the-fly applications, thus it can tolerate belt speeds and vibration conditions even in state-of-the-art fast productions lines.

Products

SCI 1-6

SCI-6 represents an innovative solution for cell sorting even in high-volume manufacturing environment.

Features and System specifications:

- Applicable Samples:

- Mono- and multicrystalline wafers

- Square or pseudo square

- Wafer Size: 100...156 mm

- Light source: 6LEDs, 400-650nm

- Available hardware interfaces:

- Parallel I/O

- Ethernet

- Other options are available upon request

- System dimensions: 233x250x236 mm (WxHxD)

- Option: Line scans up to 6