Application

BARE GLASS

Barge glass purity is the key parameter for all success process inside the fab. Semilab can offer an integrated easy to use and maintenance-free contact angle solution combined with (almost) any other metrology.

Technology

CONTACT ANGLE

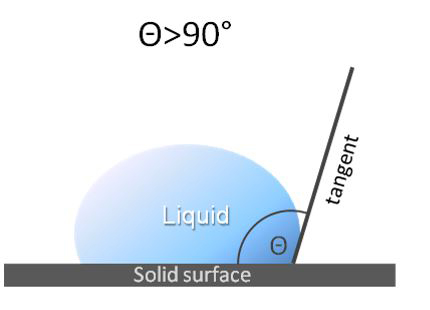

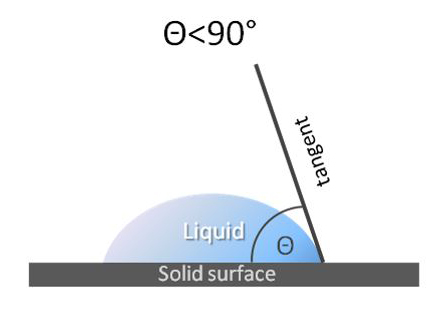

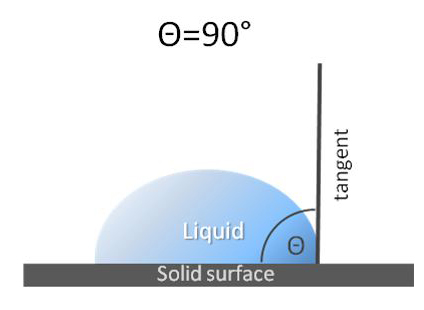

The contact angle measurement is a way of examining the wettability of a solid by a liquid in a quantitative way. The contact angle (Θ) itself is defined as the angle between the tangentials of the phase boundaries of gas to liquid and liquid to solid respectively at the point where the three medium meet.

The contact angle is determined by the equilibrium between adhesive and cohesive forces. Adhesive forces on a liquid-solid boundary cause a liquid drop to spread across the surface. Cohesive forces among the liquid particles however cause the drop to minimize its surface to the solid thus by forming small drops on the surface. The tendency of a drop to spread out over a flat, solid surface increases as the contact angle decreases. Thus, the contact angle provides an inverse measure of wettability. The used measurement technique is the sessile drop method.

METROLOGY OVERVIEW

The sessile drop contact angle is measured by a high resolution camera to capture and analyze the contact angle and the data is processed by a software. A contour line is fitted to the drop outline based on a mathematical equation. The measurement head is designed specially to make the measurement possible on large samples for the FPD industry.

APPLICATION

Contact angle measurement can be performed on all solid surfaces but our metrology is optimized for large samples for the FPD industry.

FEATURES

- Optimized for FPD industry. The structure and method is optimized for large glass samples.

- Non-destructive method

Product Line

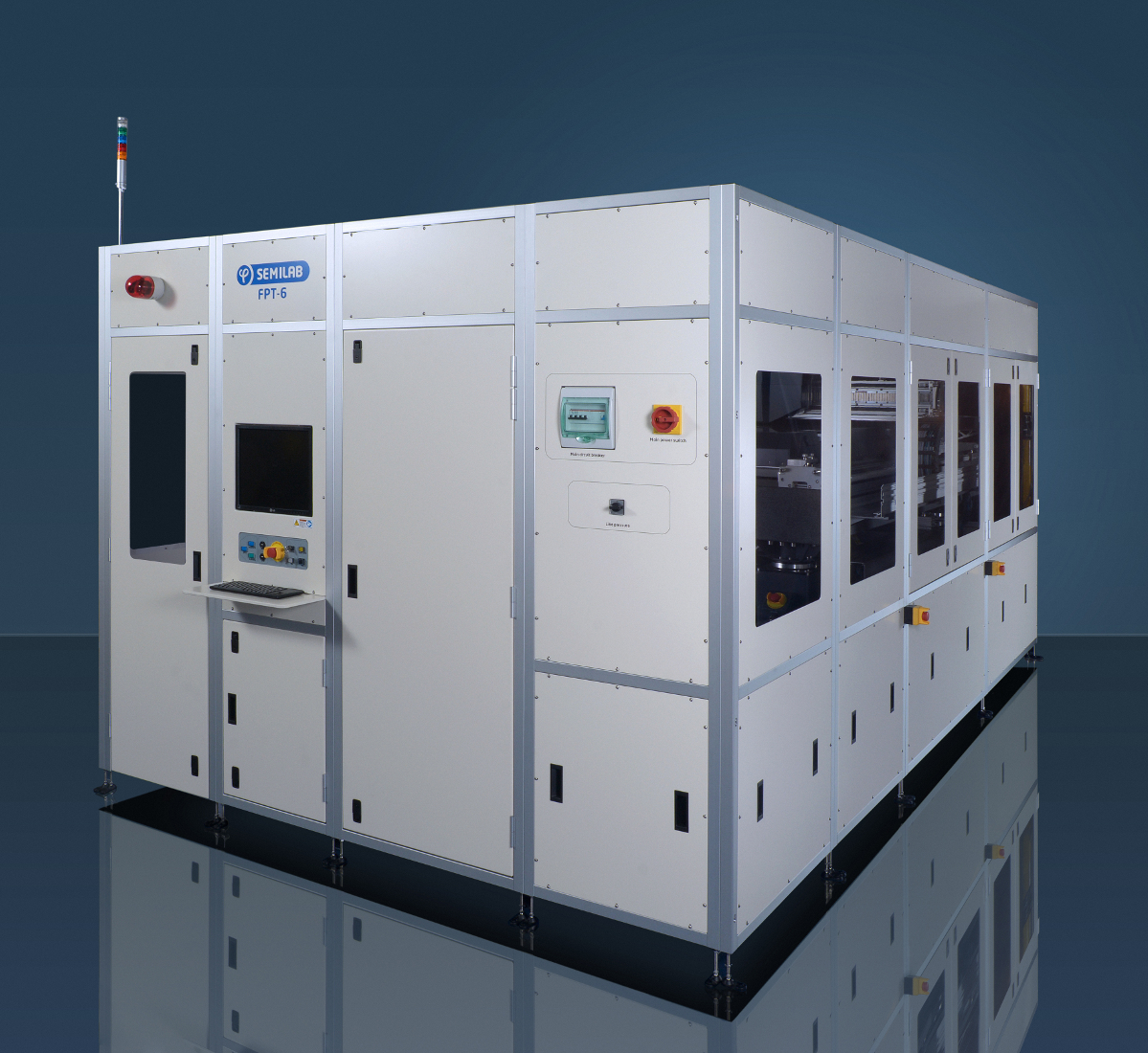

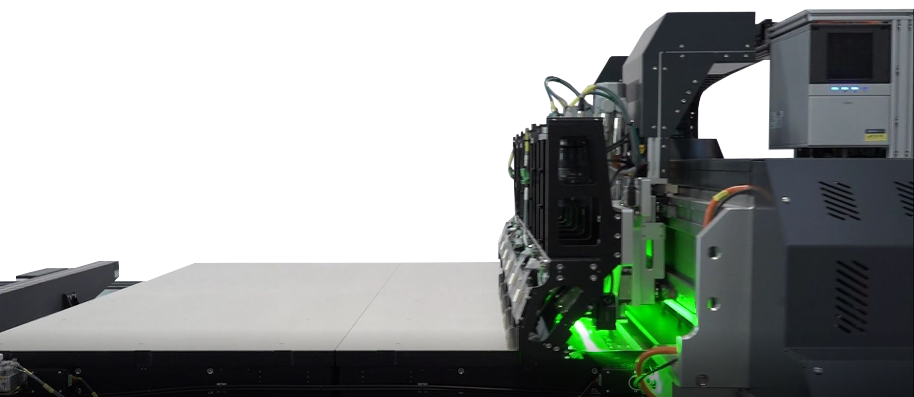

FPT

FPT- series are dedicated for flat panel testing and characterization. The products are designed to characterize LCD and AMOLED TFT panels up to GEN 8.5. It is capable to combine several measurement probes into one platform, providing high precision measurements over the entire surface of flat panels with high accuracy and fast motorization stage and weight capacity.

Products

FPT

FPT can be equipped with:

- Spectroscopic ellipsometry

- Spectroscopic reflectometry

- Imaging Spectroscopic reflectometry

- Line mura detection - Chip quality

- Microwave Photoconductive Response - Chip Quality

- Four point probe & six point probe

- Contact angle measurement

- Raman crystallinity

Optical thickness and refractive index of multilayered oxide and semiconductor structures can be determined by spectroscopic ellipsometery at different process steps. The quality of the ELA process can also be monitored by measuring crystallinity, u-PCR and line mura density. Contact angle, stress and resistivity measurements are also available.

The hardware and software are fully controlled by SEMILAB from the design to the integrated software communication with the fab.

Request Info