Application

OFFLINE PROCESS CONTROL

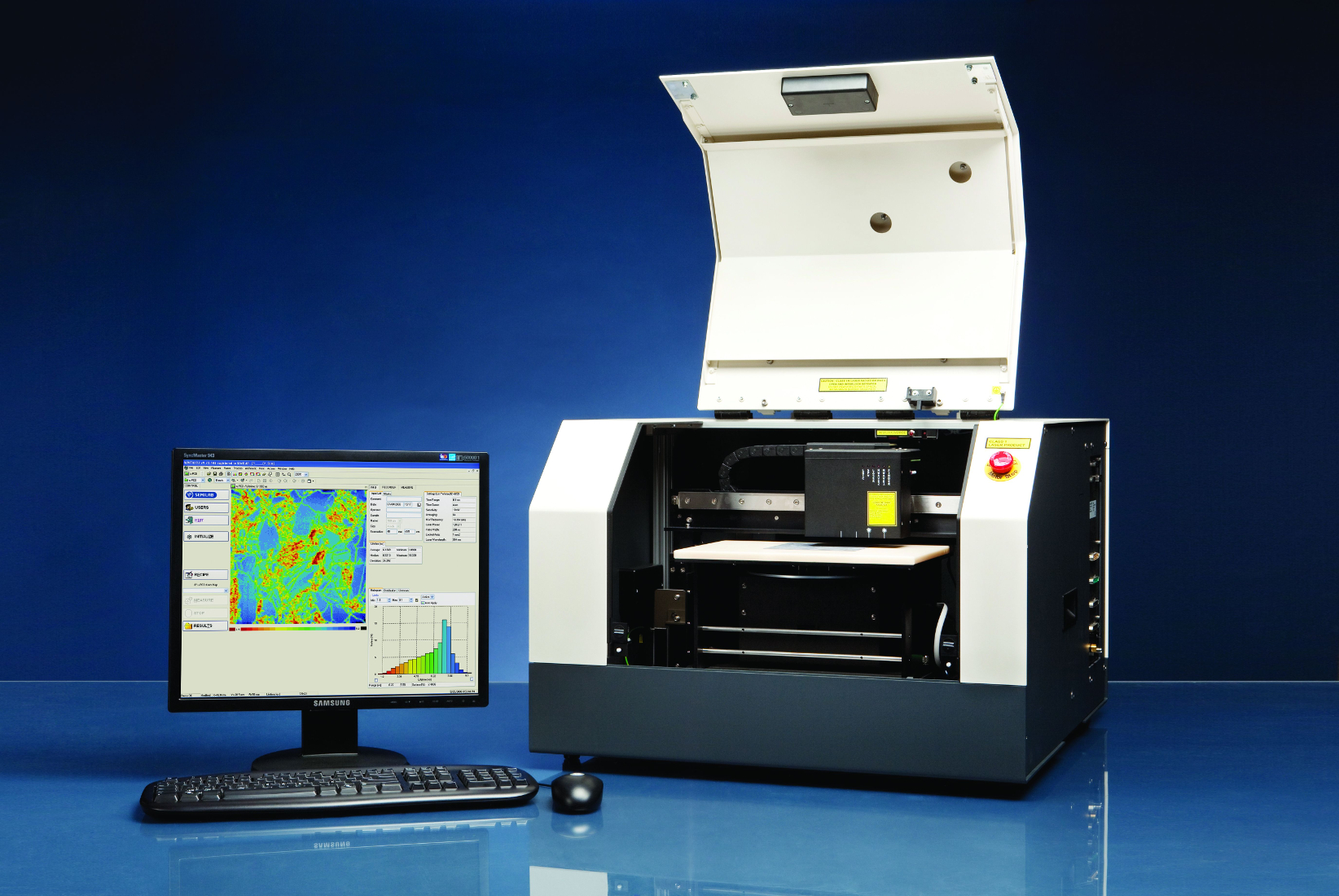

The best quality control can be achieved by inline process monitoring to check every wafer in the manufacturing process. However, in some cases the short cycle time (usually less than 1 second) does not allow to realize detailed analysis of the wafer, which may include full wafer mapping and techniques requires mechanical contacts.

The measurement tools were designed to include non-destructive techniques and favor non-contact methods where possible.

- Fast measurements

- User friendly operation

- Low cost of ownership

The applications include the followings:

- Incoming wafer characterization

- Measurement of electrical parameters in different manufacturing steps

- Characterization of deposited layer parameters

- Monitoring surface passivation efficiency and homogeneity

Technology

SINGLE-WAVE ELLIPSOMETRY

Laser ellipsometry measures a change in polarization as light reflects or transmits from a material structure. The polarization change is represented as an amplitude ratio, Ψ, and the phase difference, Δ. The measured response depends on optical properties and thickness of individual materials. Thus, ellipsometry is primarily used to determine film thickness and optical constants. However, it is also applied to characterize roughness and surface morphology by using scatter light measurement method.

FEATURES

- Non-destructive

- Non-Contact measurement method

Product Line

LE

Applications: tunnel oxide (thin SiO2 on Si), and poly-Si on SiO2/Si wafer structures monitoring

Products

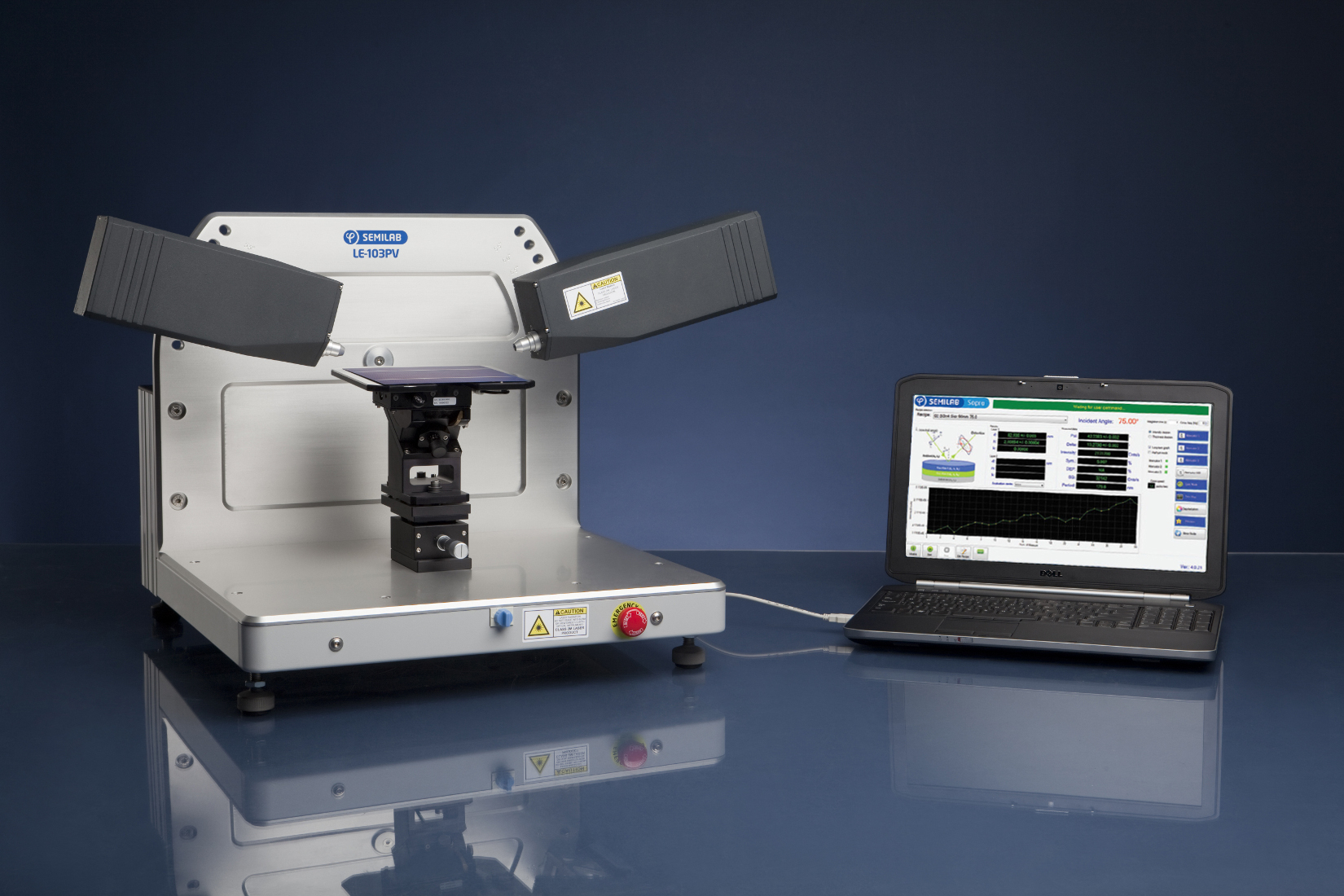

LE-103PV

Laser Ellipsometer For Silicon Solar Cells

Compact, innovative equipment designed to measure the Thickness and Optical constants of Anti Reflective Coatings deposited on textured Silicon (mono-Si & multi-Si) substrates. Optimized angle of incidence (12-90°) can be easily achieved in order to obtain a maximum signal for thin films deposited on multicrystalline structured wafers. The pyramidal structure can be oriented to obtain correct measurements while sample is maintained securely in place.

Features and System specifications:

- Determines film thickness and optical constants (refractive index and extinction coefficient) for Anti Reflective coatings

- Integrated optics for stability and auto calibration

- Rotating compensator for measurements of Psi (0° - 90°) and Delta (0° - 360°) allows increased sensitivity and calculation of the depolarization caused by rough interfaces

- Microspot focusing optics for optimum signal collection.

- Specially adapted samples holder for cell sizes of 156×156 mm.

- IN LINE integration for rapid process control.

- Smart software PVECS compliant.

- Sample alignment: Maximum signal detection for manual tilt & height adjustment.

- Sample stage: 156 × 156 mm compatible

- Goniometer: 55° - 90° manual control