Application

OFFLINE PROCESS CONTROL

The best quality control can be achieved by inline process monitoring to check every wafer in the manufacturing process. However, in some cases the short cycle time (usually less than 1 second) does not allow to realize detailed analysis of the wafer, which may include full wafer mapping and techniques requires mechanical contacts.

The measurement tools were designed to include non-destructive techniques and favor non-contact methods where possible.

- Fast measurements

- User friendly operation

- Low cost of ownership

The applications include the followings:

- Incoming wafer characterization

- Measurement of electrical parameters in different manufacturing steps

- Characterization of deposited layer parameters

- Monitoring surface passivation efficiency and homogeneity

Technology

CARRIER LIFETIME (µ-PCD, QSS-µPCD)

Microwave detected PhotoConductance Decay (µ-PCD) Carrier lifetime measurement is a useful technology for incoming wafer inspection, quality control and process monitoring in wafer manufacturing as well as in solar cell manufacturing. The microwave induced photoconductive decay method is the most common way of measuring minority carrier lifetime in silicon. This method excels due to its reliability, good reproducibility and the short measurement time that permits of making lifetime maps with high resolution.

Frequent contaminants and their lifetime killing efficiency:

|

Level of influence |

Element |

|---|---|

|

Strong |

Fe, Pt, Cu |

|

Medium |

Pd |

|

Weak |

Mo, W |

|

Negligible |

Ca, Al, Zn, Ti |

A contaminant may exist in two molecular states, with different effects on lifetime (or diffusion length).

The change in lifetime, caused by changing the state of the contaminant, measures the amount of that contaminant:

- Requires a unique method of changing states

- Constants are derived empirically

- The effect of a contaminant on lifetime may be dependent on injection level

- Change can be detected by μ-PCD or SPV technique

µ-PCD technique

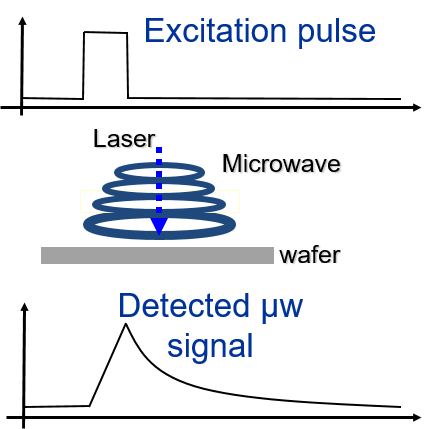

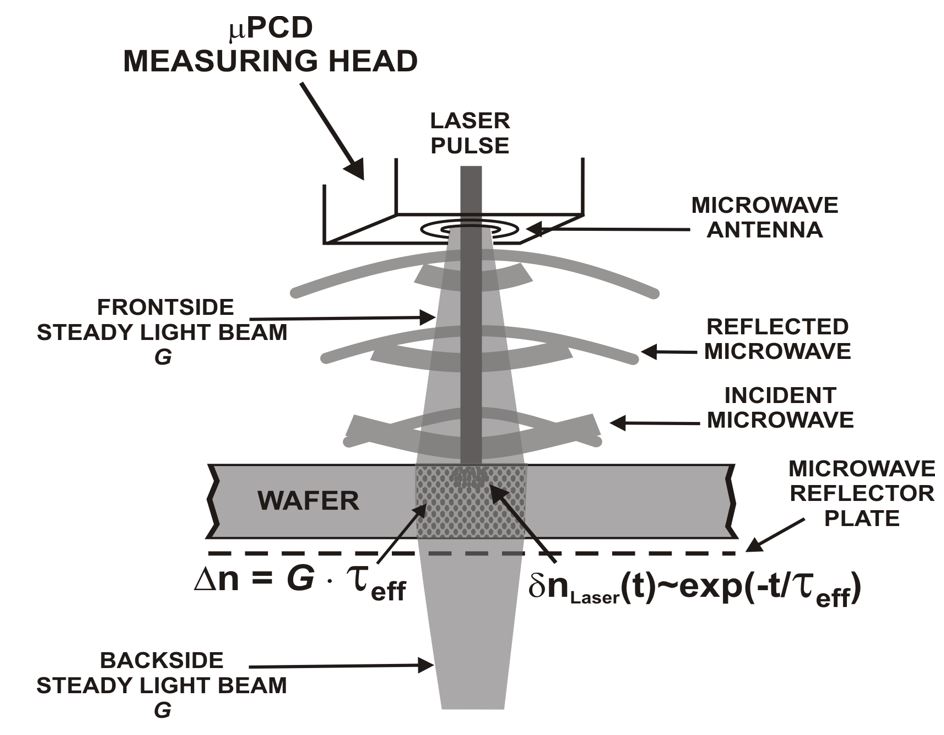

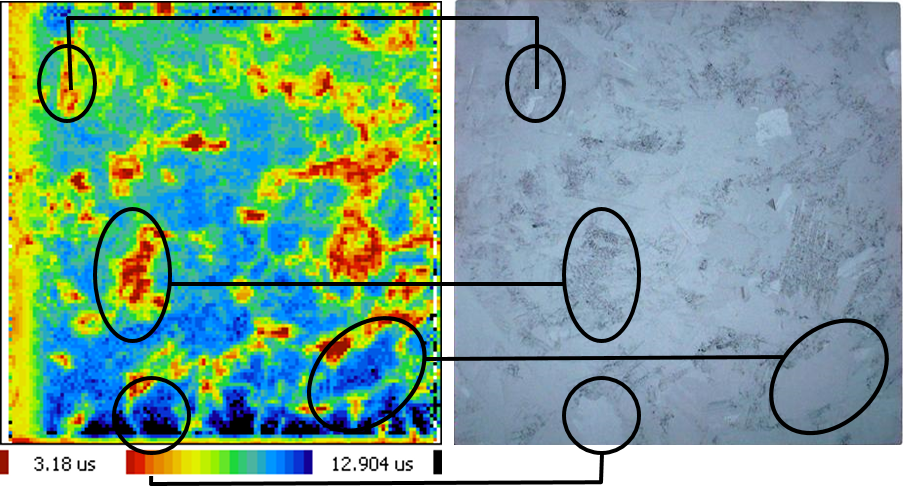

It is a metrology of recombination properties and defects used in silicon photovoltaics and IC manufacturing as well. The technology is based on pulse of laser light, which generates carriers. Excited carriers change the conductivity of semiconductor. The microwave reflection is sensitive to change in conductivity measured signal shows decaying of conductivity. The objective of the monitoring is the bulk lifetime parameter, because that gives information about the contaminations and dislocations.

Role of Crystallinity in case of Multicrystalline Silicon:

Different lifetime can be observed on different grains

Quasi-Steady-State Microwave detected PhotoConductance Decay

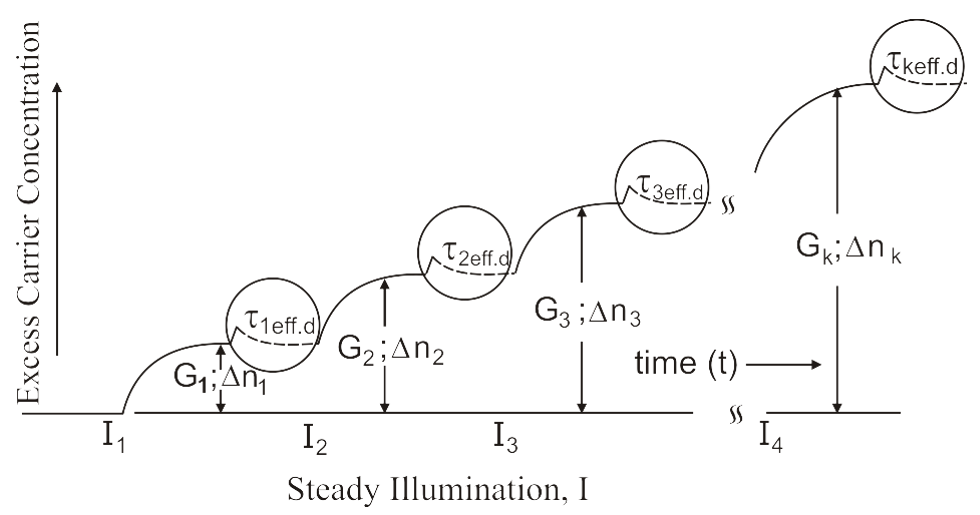

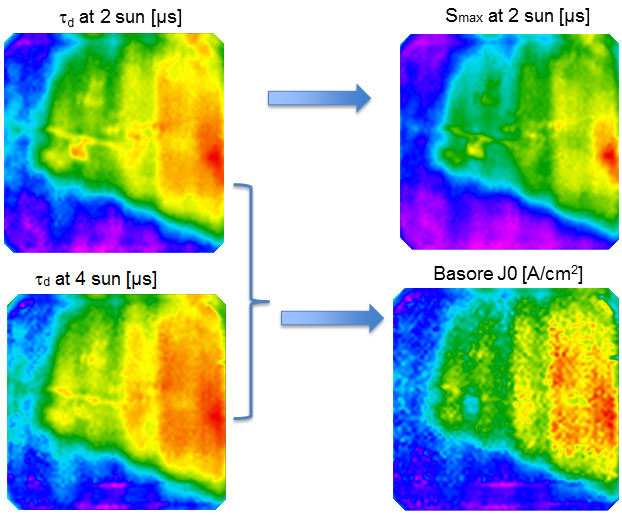

A new powerful version of the technique introduced by Semilab is termed, QSS-μPCD with QDC i.e. the Quasi-Steady-State Microwave (detected) Photoconductance Decay with Quality of Decay Control. It gives enhanced accuracy, new capabilities and broader applications. The technique represents a unified lifetime measurement for silicon PV wafers that enables self-consistent parameter-free determination of two lifetimes most-frequently used in solar cell manufacturing, i.e. the excess carrier decay lifetime, Ʈeff.d, and the quasi-steady-state effective lifetime, Ʈeff.ss. This provides a basis for determination of other recombination parameters important for PV over a broad range of steady-illumination. The technique retains unique wafer mapping advantages of μ-PCD.

In QSS-μPCD technique a decay lifetime measurement is done using a small perturbation transient condition imposed on the steady-state condition. The steady light is turned on to achieve the steady-state condition. Then the short laser pulse generates additional free carriers, and their decay is monitored to determine the decay time constant.

The laser excitation is small compared to steady-state carrier excitation small perturbation condition is well satisfied.

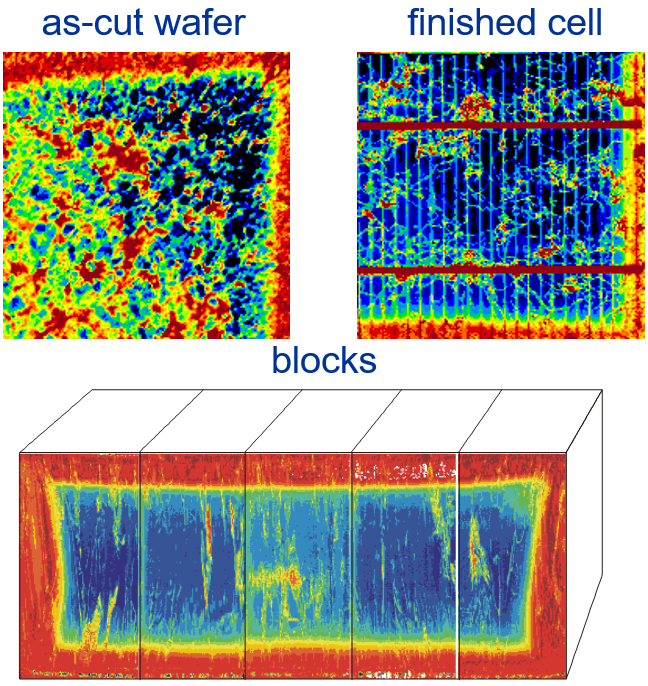

Example of typical QSS-µPCD maps:

FEATURES

- Suitable material to measure:

- Blocks

- As-cut wafers

- Lapped wafers

- Diffused wafers

- Coated wafers

- Finished cells

- Mono-, multicrystalline and EFG material

- Parameter free, non-contact method, suitable for mapping

- Small laser spot diameter

- Suitable material to measure: Passivated surface Si wafers with QSS-µPCD

Product Line

WT, PV

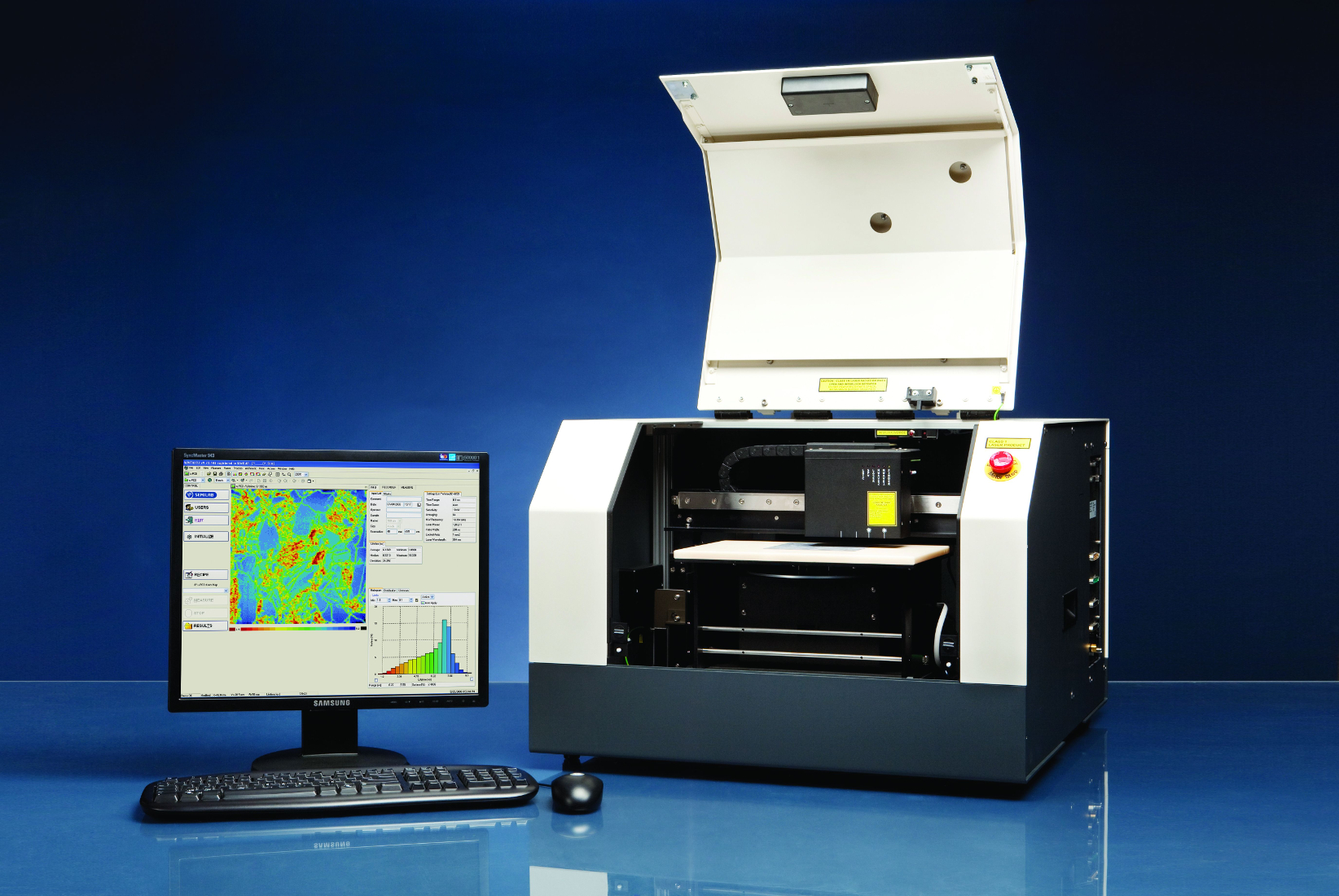

Measurement technique is µ-PCD, which is applicable for incoming wafer inspection, sorting and after emitter diffusion for efficiency prediction.

Products

WxL

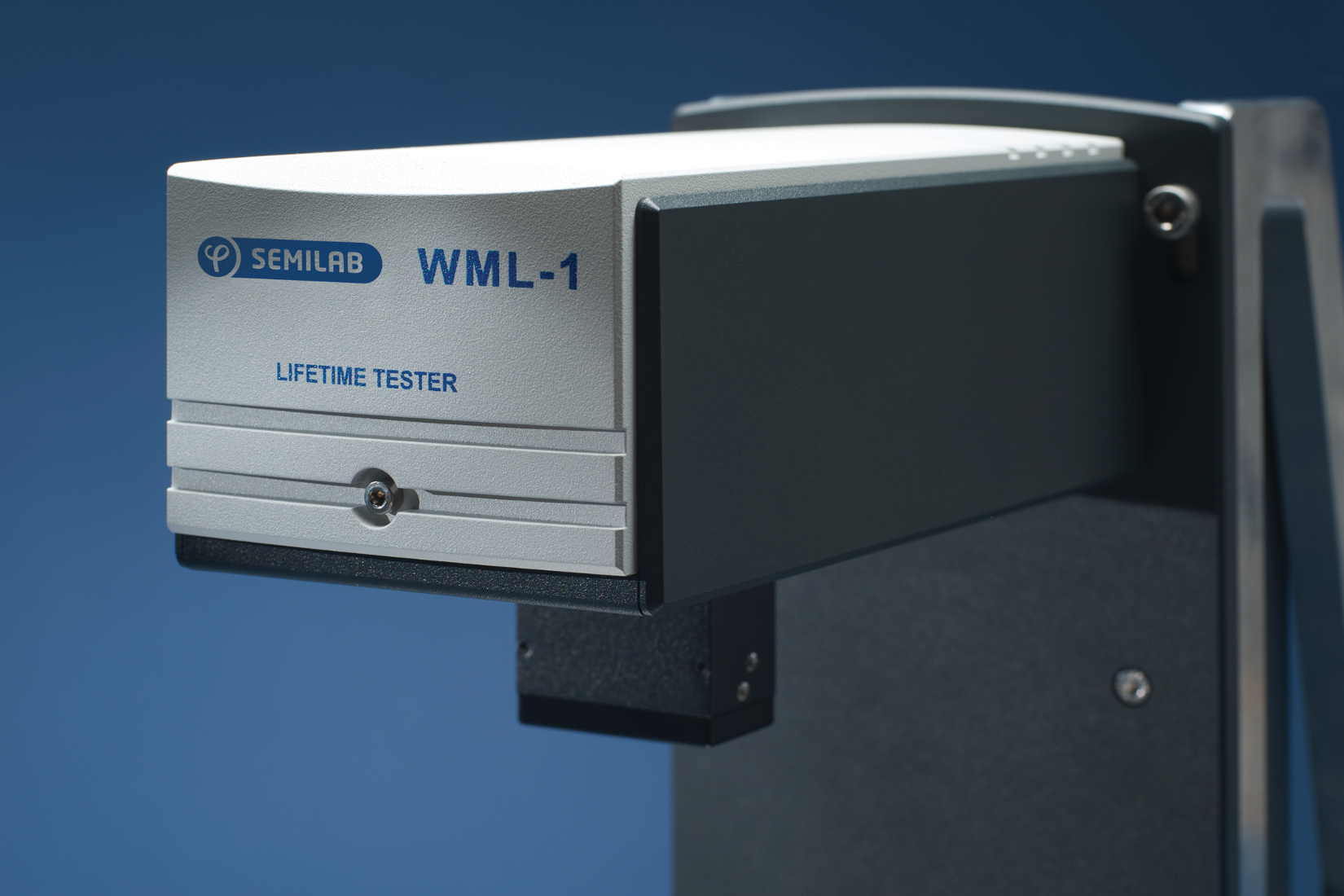

WML

Carrier lifetime is a primary quality control parameter for silicon wafers in PV applications. The WML models, WML-1 & WML-3, Lifetime Testers allow measurement of wafers “on the fly," i.e., conveyor belt does not stop during measurement. Therefore, they have the high throughput that meets the requirements of in-line quality control in fully automated wafer and cell production lines.

WLL

FAST NON-CONTACT MATERIAL CHARACTERIZATION AND PROCESS CONTROL

Carrier lifetime is a primary quality control parameter for silicon wafers in PV applications. The WLL models, WLL-1, -3 & -5 In-Line Lifetime Testers allow measurement of lifetime at 1, 3 or 5 points with the high throughput that meets the requirements of in-line quality control in fully automated wafer production lines.

- measurement technique: µ-PCD

- sample size: 100 to 210 mm

- measurement position: adjustable

- probe height above transport belt: 4 mm

- sample support: on belt

WT-1200 & WT-1200B

Low Cost, Non-Contact Single-Point Measurement in Silicon

Both WT-1200 and WT-1200B provide fast, non-contact carrier lifetime measurement method that is capable of characterizing silicon material in each process step of solar cell manufacturing.

WT-1200 is designed to measure wafers from as-cut wafer to the finished solar cell. WT-1200B is a model for block measurements.

Features and System specifications:

- No need for access to back side of the wafer

- Fully automatic operation and data evaluation

- Measurement selectable at any position on the wafer

- Measurement of mono- and multi-crystalline material

- Patented chemical surface passivation option available for wafers

- Wafers can be measured after each process step of solar cell manufacturing:

- Incoming as-cut wafer

- Diffused wafers (with or without phosphorous glass)

- Nitride coated wafers

- Metallized wafers

- Finished solar cells

WT-1200A

Quasi-Steady-State µ-PCD whit Quality of Decay control (QSS µ-PCD QD). Quality control of wafers and solar cells at different stages of production.

Measured parameters:

- Parameter free determination of Steady State Lifetime and Injection level

- Surface Recombination Velocity (Smax)

- Implied Voc

- Emitter Saturation Current (J0)

Features and System specifications:

- Fully automatic operation and data evaluation

- Measurement selectable at any position on the wafer

- Measurement of mono- and multi-crystalline material

- Patented chemical surface passivation option available for wafers

- Lifetime of wafers can be measured after each process step of solar cell manufacturing:

- Incoming as-cut wafer

- Diffused wafers (with or without phosphorous glass)

- Nitride coated wafers

- Metallized wafers

- Finished solar cells

- Advanced parameters (Smax, Voc, J0) can be measured after surface passivation steps

PV-2000A

Features and System specifications:

It is a new integrated platform with the following capabilities:

- SPV Diffusion Length

- Discrete ites and mapping of incoming and processed wafers to final cells.

- UV/Blue SPV ratio for surface passivation (arb. units)

- Monitorable parameters:

- Diffusion length (L)

- Fe contamination (Fe)

- Other Recomb. Centers (NR)

- LID Defect Contamination

- Noncontact C-V profiling

- Time resolved approach with leakage correction

- Monitorable parameters:

- Flatband Voltage (Vfb)

- Oxide Total Charge (Qtot)

- Interface Trapped Charge (Qit)

- Interface Trap Density (Dit)

- Dielectric Capacitance (CD) and thickness (CET),

- Dielectric Leakage and PID testing 3 to 1000 nm planar and textured films

- Accelerated LID testing

- Temperature stages (20-220°C), 2 illumination stations (halogen and flash); robotic handling: activates/deactivates iron and/or boron-oxygen

- LID defects in minutes

- ALID is sequenced with SPV for Fe and LID defect mapping in short time

- Applicable to wafers and solar cells

- QSS-μPCD

- Discrete sites and mapping of incoming and processed wafers

- PCD laser wavelength: 904 nm

- Monitorable parameters:

- Decay lifetime (τ eff.d)

- Steady-state lifetime (τ eff.ss)

- Injection level (Δn)

- Effective surface recombination (Seff)

- QSS light intensity: 0.005 to 30 Suns

- Emitter Saturation Current (J0)

- Implied Voc

- Light Beam Induced Current (LBIC)

- Mapping of solar cells 1 to 4 lasers

- Measurement parameters: Current; Diffusion Length; Reflectance; Internal Quantum Efficiency (IQE)

- Reflectance measurement and IQE mapping

Other testing capabilities:

- SPV Surface Lifetime

- SPV Mapping of Rshunt and Voc

- Noncontact Suns-Voc

- Wafer Thickness Measurement