Application

NANOINDENTATION

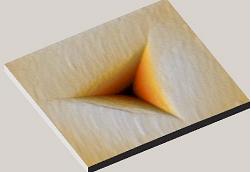

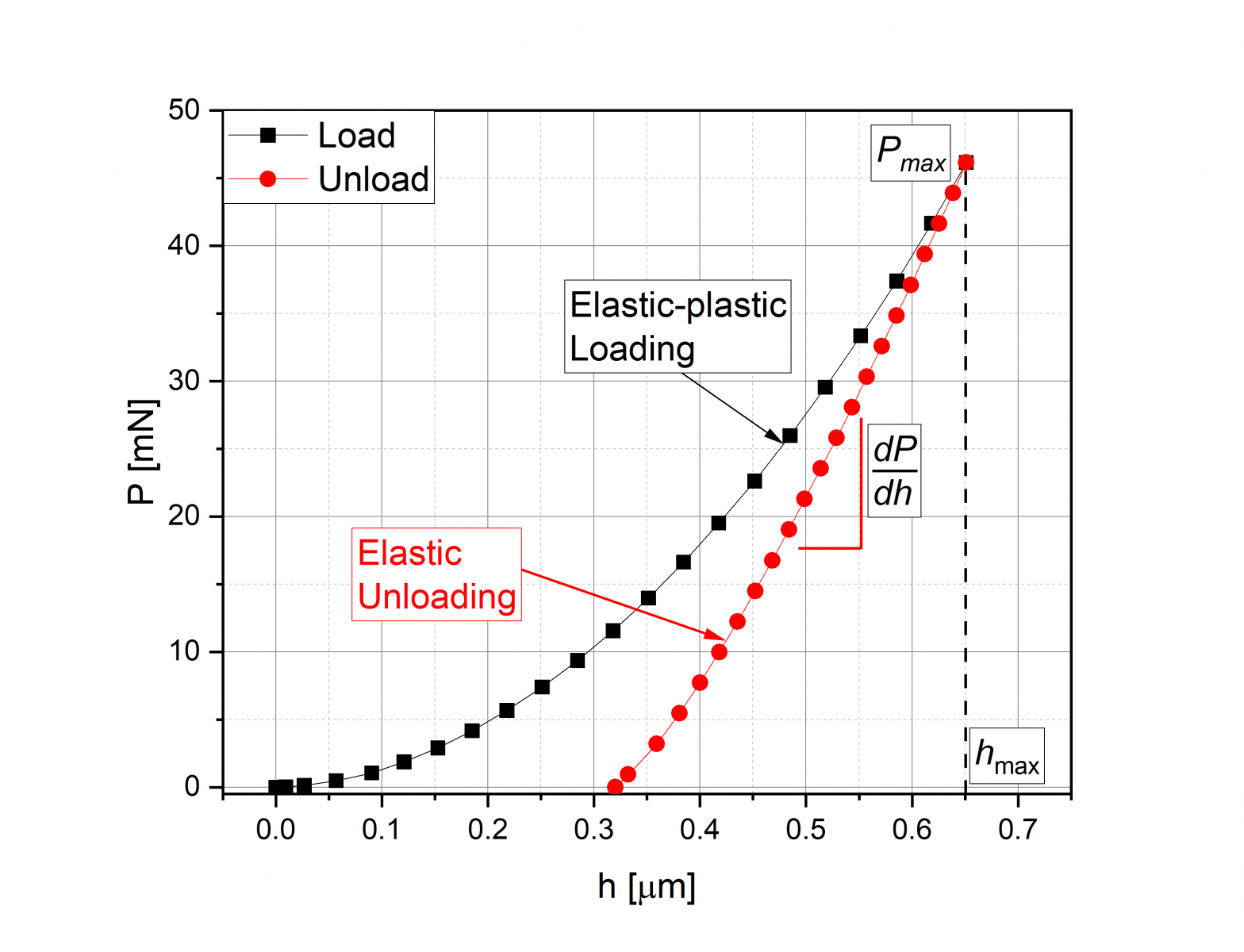

Nanoindentation is the key for unlocking quantitative mechanical properties of small volumes of materials. This technique is now a well-established method for determining elastic, plastic and visco-elastic properties of materials like hard thin films, multi-phase metals, ceramics, soft films, semiconductors, biological materials and plastics on a micron to nanometer scale.

Technology

NANOINDENTATION

| A nanoindentation test provides precision load displacement curves for testing on both soft and hard surfaces, and also rough surfaces such as those deposited by industrial processes including thermal spray coatings by quantitively measure the mechanical properties of small volumes of materials. Thin films, multi-phase metals and ceramics, biological materials, etc are the main applications for such instruments but they can also be used for viscoelastic measurements of polymers, flexure testing of MEMS and any application involving mechanical measurement on the sub-micron scale. The materials properties measured are elastic modulus and hardness, yield strength, and depending on the sample, storage and loss moduli, fracture toughness, scratch and wear properties. |  |

FEATURES

|

|

Product Line

NANOINDENTATION TESTER

|

The IND nanoindentation tester system of Semilab is designed to provide a controlled load and deformation of the material being tested. The mechanical response of the material is measured via force and displacement sensors. The range of the actuator, force and displacement sensors, is on the micro- and nanoscale with resolution of nanonewtons and nanometers. The precise nature of the measurement enables us events on the micro- to nanoscale to be recorded. Macroscale damage can thus be interpreted and explained by events on the submicron scale thus allowing the fundamental properties of the sample to be studied and tailored for specific applications. The force sensor of IND system tools is completely separate from the load actuator and measures the force applied to the indenter directly. Force and depth sensors are independently calibrated against international standards. Closed loop feedback can be selected either for the force or for the depth sensor. Open loop mode of operation for high speed data acquisition is also possible to select. The IND system is almost immune to mechanical breakage due to a specially designed safety gap between the shaft and piezo actuator. Nanoindenter systems use rugged LVDT sensors for both force and depth measurements. Advanced AC amplification provides mV noise floor. Special circuitry offsets the signal to take advantage of the full range of analog to digital converter. |

|

Products

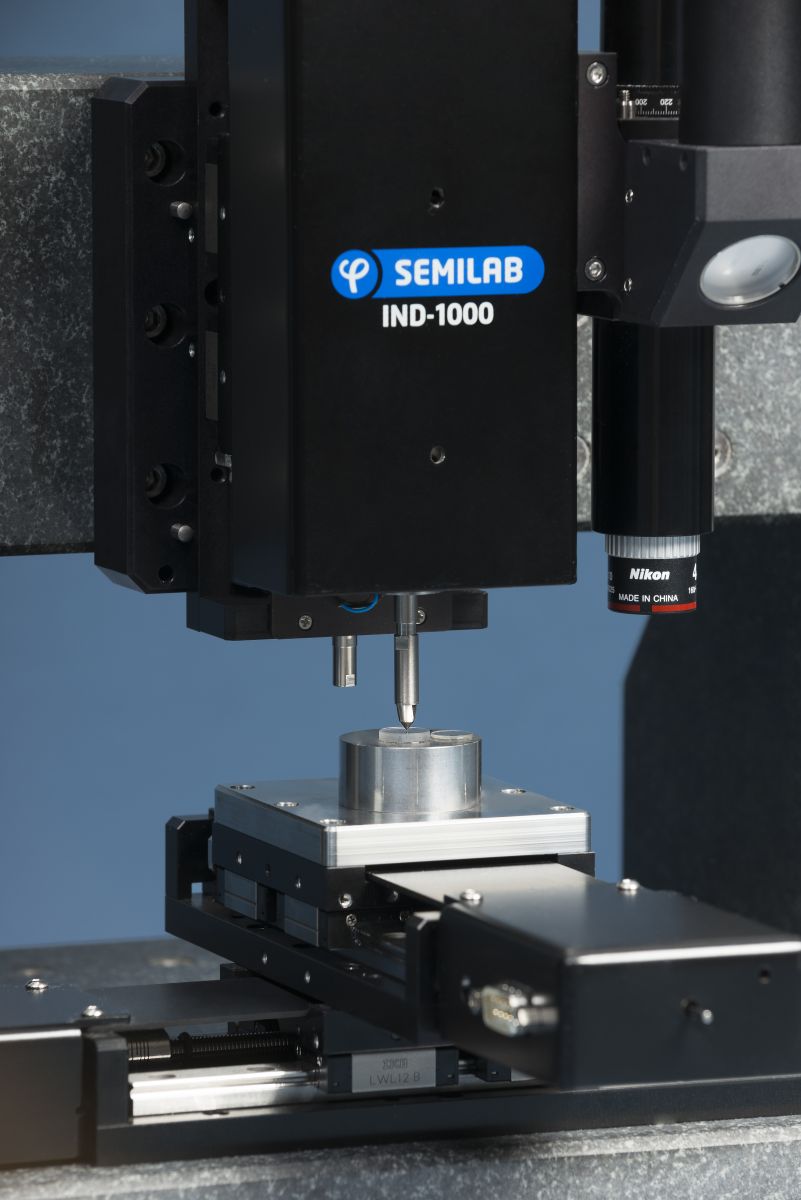

IND-1000 Tabletop Nanoindentation Basic System

The table top nanoindentation system of Semilab is IND-1000. This equipment is applicable for wide range of applications from medium to high load range.

Benefits:

- Measured material properties: Elastic Modulus, Hardness, Yield Strength, Storage and Loss Moduli, Fracture Toughness, Scratch and Wear properties (depending on the sample)

- Closed loop force/depth feedback

- Sub-nanometer depth resolution and extremely linear response LVDT

- High quality PZT expansion element, no heat generation

- Realtime feedback control over application of load- or depth-independent force and displacement measurement

- Precise sample positioning is ensured by video microscope and automated X- Y- Z-movement

- Low compliance load frame, enclosure and mountings

- Traceable calibration

- Periodic calibration is not required

- Easy indenter tip changeover

- Robust design can withstand significant abuse

- Reliable performance for many years

- Almost immune to mechanical breakage unlike competitor instruments

- The technology is based on the successful nanoindentation system of Fischer-Cripps Laboratories.

Optional feature:

- Atomic Force Microscope

Request Info

IND-1500 Nanoindentation Advanced System

IND-1500 is an advanced nanoindentation tester with closed and isolated enclosure, improved noise and vibration isolation. This equipment is applicable for thin film characterization even on samples with 150-200 nm of thicknesses.

Tool features:

- Precise sample positioning is ensured by video microscope and software-driven X, Y, Z movement

- Measured material properties:

- Elastic Modulus, Hardness, Yield Strength, Storage and Loss Moduli, Fracture Toughness, Scratch and Wear properties (depending on the sample)

- Closed loop force/depth feedback

- Easy indenter tip changeover

- Low compliance load frame, enclosure and mountings

- Traceable calibration

- Choice of staging and microscope to suit budget

Benefits:

- Better vibration discharge

- Better voice isolation

- Depth resolution in nanometer scale and extremely linear

response LVDT

- High quality PZT expansion element, no heat generation

- Real time feedback control over application of load or depth

- Independent force and displacement measurement

- Robust design can withstand significant abuse

- Reliable performance for many years

- Almost immune to mechanical breakage unlike competitor’ s instruments

- Periodic calibration is not required

Optional feature:

- Atomic Force Microscope