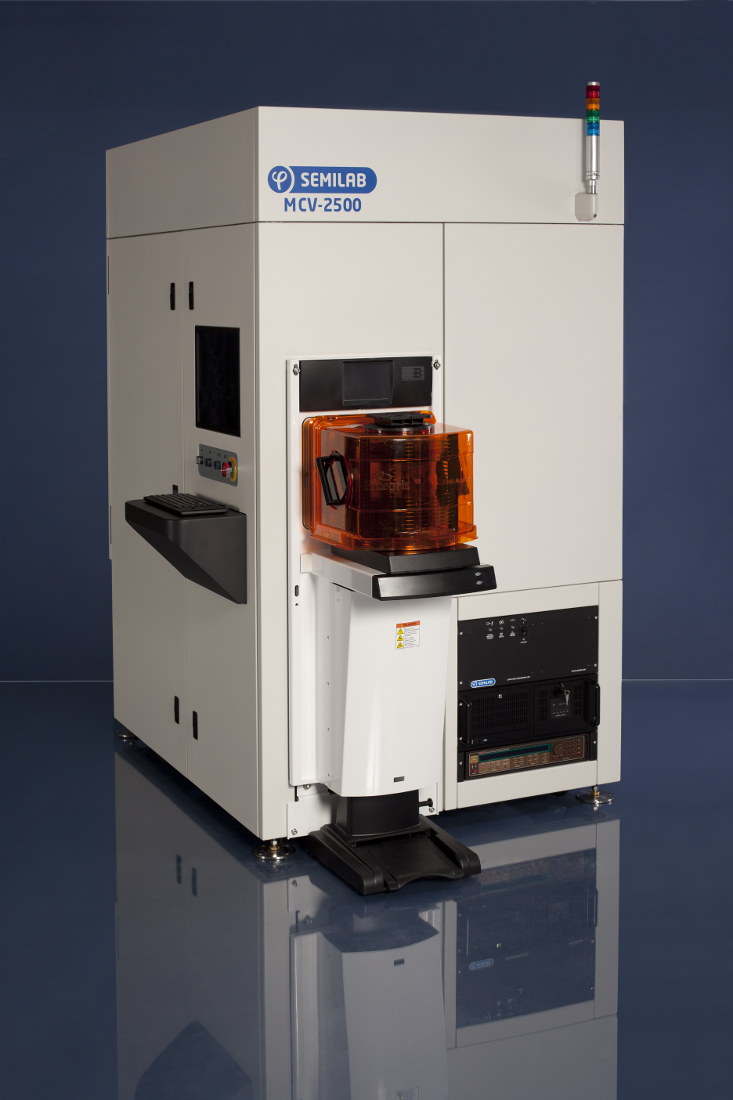

MCV-2200, MCV-2500, MCV-3000, MCV-3000P

The MCV automatic mapping systems provide a Mercury C-V measurement for non-patterned wafers used in epitaxial silicon production and front-end semiconductor processing.

In MCV-2200, MCV-2500 and MCV-3000/3000P the wafers are robotically loaded onto the mapping stage from an open cassette or FOUP. The test wafer moves to each site specified in a pre-programmed map as electrical characterization tests are made. The system stores test data and reports them in a variety of formats.

Optional features:

- ID reader (front or back, even in case of transparent samples like SiC, GaN)

- SECS/GEM host communication

- Pre-treatment chamber option

- Can be configured with 300 mm FOUP, 200 mm SMIF or open cassette

Wafer sizes:

- Automatic wafer handling:

- MCV-2200: from 100 mm to 200 mm

- MCV-2500: from 200 mm to 300 mm

- MCV-3000/3000P: 200 mm or 300 mm

- Manual wafer handling:

- Full wafers:

- MCV-2200: from 50 mm to 200 mm

- MCV-2500: from 50 mm to 300 mm

- Coupon samples or fractions:

- minimum sample size is 40 mm × 40 mm

- Full wafers: