Application

SHEET RESISTANCE MEASUREMENT

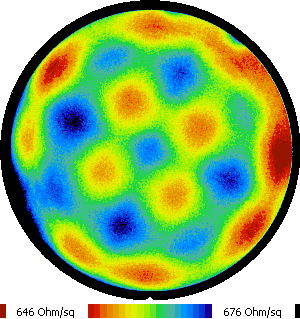

The combination of the ion implant process and the process to anneal implants is usually monitored by measuring the sheet resistance of the implanted layer. The sheet resistance varies with dose, energy, and the amount of implanted species that has become electrically active. It is the sheet resistance that ultimately determines the device performance. Thus, measuring sheet resistance is an excellent way to monitor everything associated with an implant process.

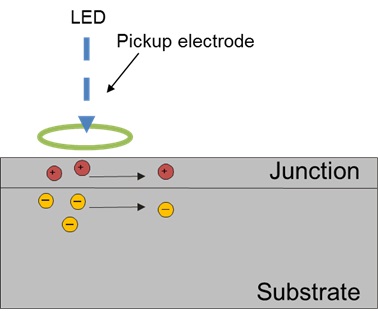

The basic idea of the JPV method is the light excitation of the np or pn layer structure, and the pick-up of the resulting junction photovoltage by a capacitive probe. The detected potential is determined by the sheet resistance of the implanted layer, capacitance of junction and resistance through over the diode.

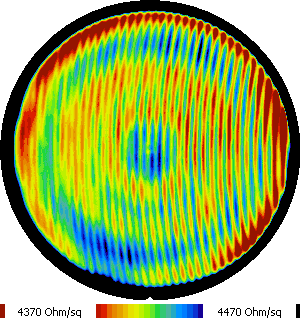

Figure 2. Sheet resistance measurement (lower range)

Figure 3. Sheet resistance measurement (higher range)

Semilab offers JPV technology to make non-contact, high resolution fast maps of sheet resistance.

MEASUREMENT THEORY:

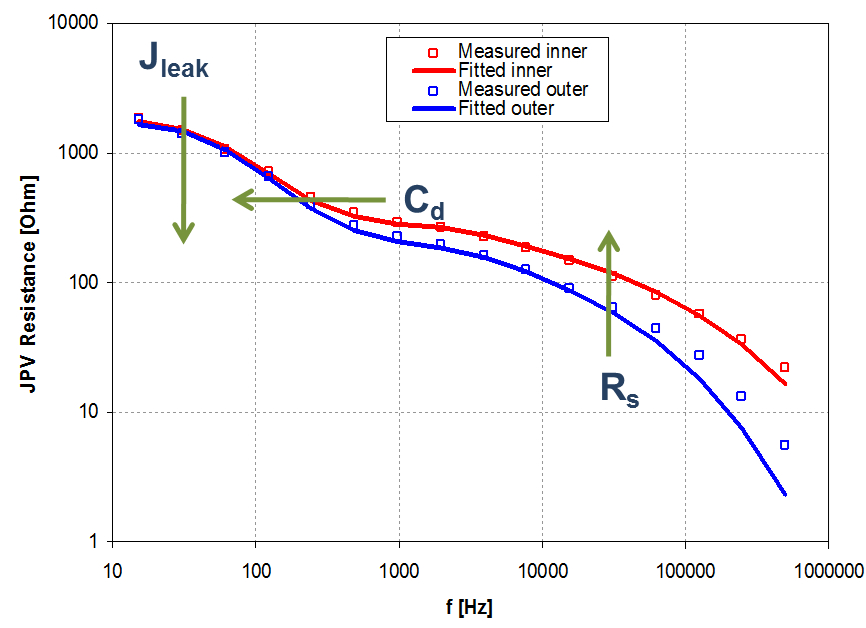

The sample is illuminated by chopped LED light, which generates electrons and holes in the substrate layer. The generated charge carriers diffuse to the junction and the electric field located in the junction separates them. The result of the separation is the change in the junction voltage. This voltage change spread laterally in the implanted layer and the attenuation depends on the sheet resistance, junction capacitance, resistance of the junction and chopping frequency of the LED.

The potential change is detected by a capacitive sensor in order to evaluate the JPV signal, as a function of the frequency of the emitted light.

Based on the evaluation, the sheet resistance (Rs), capacitance of junction (Cd) and the resistance of the diode (Rd) can be calculated.

The junction leakage current is directly connected to the Rd by the following equation:

I_L=kt/q/R_d

Figure 5. The detected potential is determined by Rs, Cd, Rd and frequency

Technology

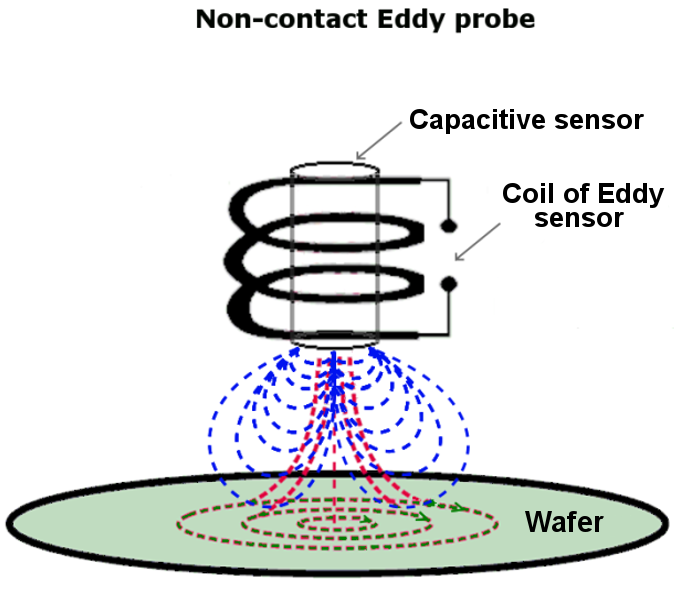

NON-CONTACT SHEET RESISTANCE MEASUREMENT

Sheet resistance measurement of thin films can be realized with help of non-contact, non-destructive Eddy current technique. When AC current flows in a coil, its magnetic field induces circulating (eddy) currents in the sample. The eddy current measurement is actually the measurement of the electrical loss in the material. The measuring head moves above the sample in constant height without touching it. Because the measured signal depends on sample sheet resistance, and distance between the probe and sample, there is built-in distance sensor (based on capacitance measurement), which measures in the same spot like eddy sensor. From the distance value and the eddy signal, true sheet resistance values can be obtained.

The eddy current is higher in good conducting material compared to less conductive material.

FEATURES

- Non-contact, non-destructive method

- Alternative method to the traditional four-point-probe

- Sample preparation free

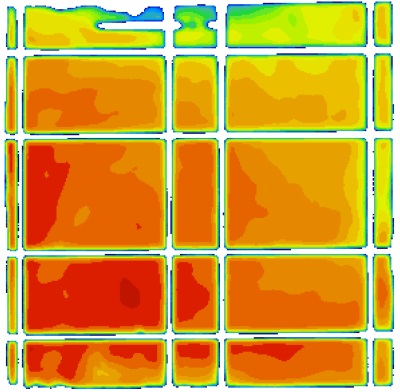

- Capable of full mapping (with 10 mm edge exclusion) with fast tact time

- With certain limitations measurement is possible even on partly metallized panel

Product Line

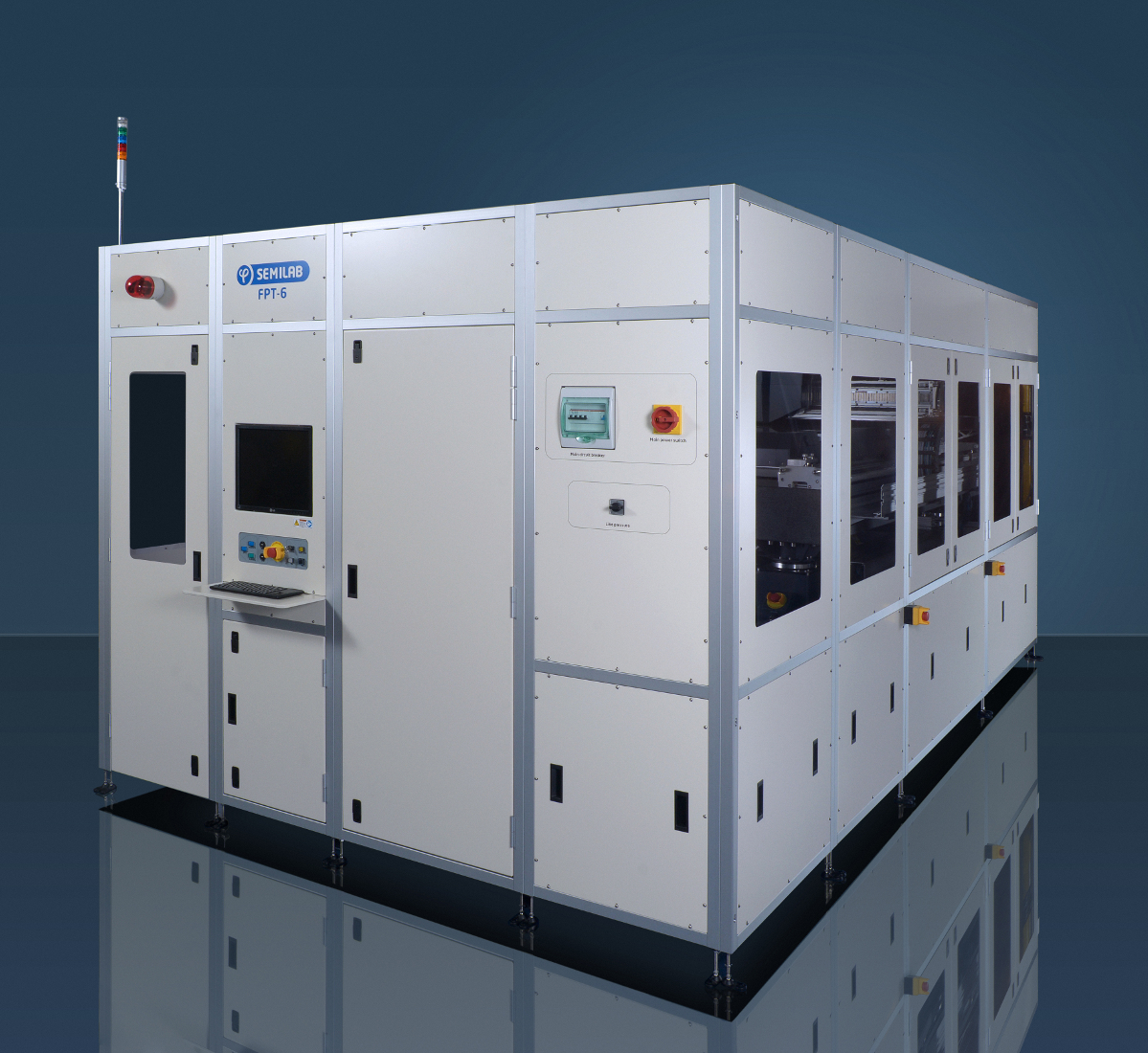

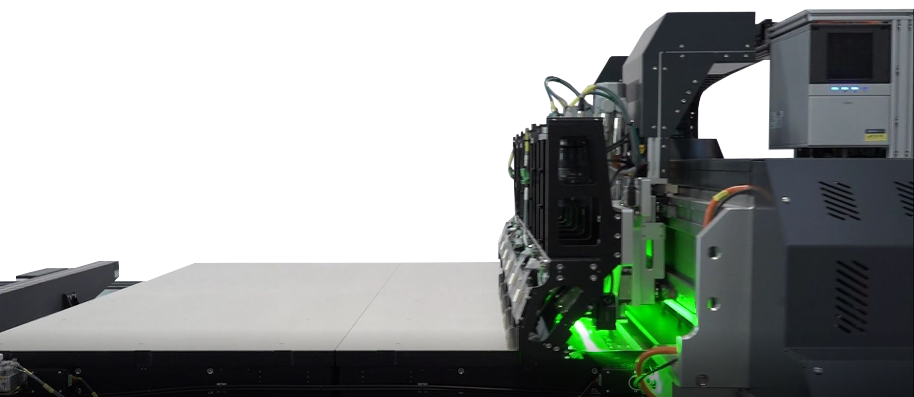

FPT

FPT- series are dedicated for flat panel testing and characterization. The products are designed to characterize LCD and AMOLED TFT panels up to GEN 8.5. It is capable to combine several measurement probes into one platform, providing high precision measurements over the entire surface of flat panels with high accuracy and fast motorization stage and weight capacity.

Products

FPT

FPT can be equipped with:

- Spectroscopic ellipsometry

- Spectroscopic reflectometry

- Imaging Spectroscopic reflectometry

- Line mura detection - Chip quality

- Microwave Photoconductive Response - Chip Quality

- Four point probe & six point probe

- Contact angle measurement

- Raman crystallinity

Optical thickness and refractive index of multilayered oxide and semiconductor structures can be determined by spectroscopic ellipsometery at different process steps. The quality of the ELA process can also be monitored by measuring crystallinity, u-PCR and line mura density. Contact angle, stress and resistivity measurements are also available.

The hardware and software are fully controlled by SEMILAB from the design to the integrated software communication with the fab.

Request Info