Application

OFFLINE PROCESS CONTROL

The best quality control can be achieved by inline process monitoring to check every wafer in the manufacturing process. However, in some cases the short cycle time (usually less than 1 second) does not allow to realize detailed analysis of the wafer, which may include full wafer mapping and techniques requires mechanical contacts.

The measurement tools were designed to include non-destructive techniques and favor non-contact methods where possible.

- Fast measurements

- User friendly operation

- Low cost of ownership

The applications include the followings:

- Incoming wafer characterization

- Measurement of electrical parameters in different manufacturing steps

- Characterization of deposited layer parameters

- Monitoring surface passivation efficiency and homogeneity

Technology

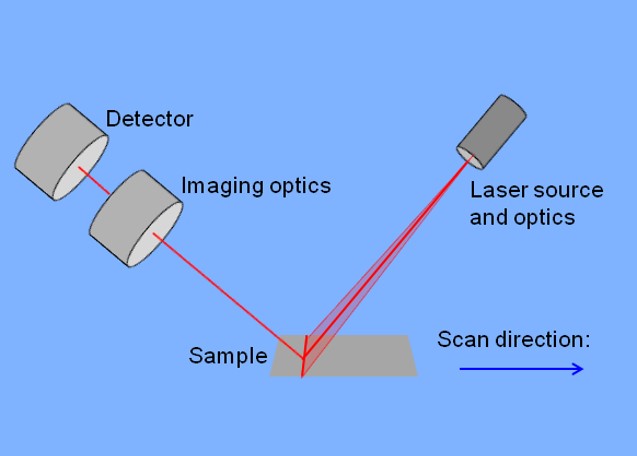

PHOTOLUMINESCENCE IMAGING

Photoluminescent Imaging is an excellent tool for monitoring of multicrystalline, monocast or monocrystalline wafers. During the measurement, the laser illuminates the silicon block and the generated photoluminescent signal is detected by an IR camera. The illumination effects the recombination of charge carriers. If not, the defects are present and there is a chance of radiative recombination. During the radiative recombination, a photon is emitted which can be detected by an IR camera. PL intensity is inversely proportional to defect density and impurity concentration.

System features:

- High quality fast imaging even for as cut wafers

- Advanced on-the-fly lifetime calibration method

- Flexible classification according to the particular requirements

- Detection of wafers with broken edge

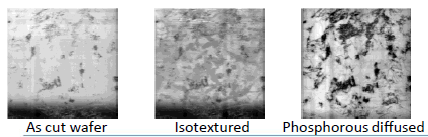

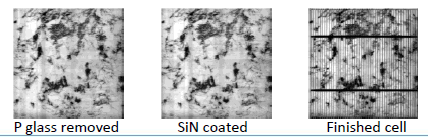

- Capability to measure solar wafers at any processing stage providing full process control

- Accurate tool matching capability

- Cell efficiency forecast capability at as-cut stage

- Flexible configurability from stand-alone to integration in fully automated systems

TYPES OF DETECTABLE DEFECTS:

1. Material (as-cut wafers):

General

- High contamination density

- Edge (corner) contaminations

Multi wafers

- High dislocation density

- Active grain boundaries

Mono wafers

- Ring defects (for different reasons)

- Pinholes

- Cracks

2. Passivation control (double side passivated samples)

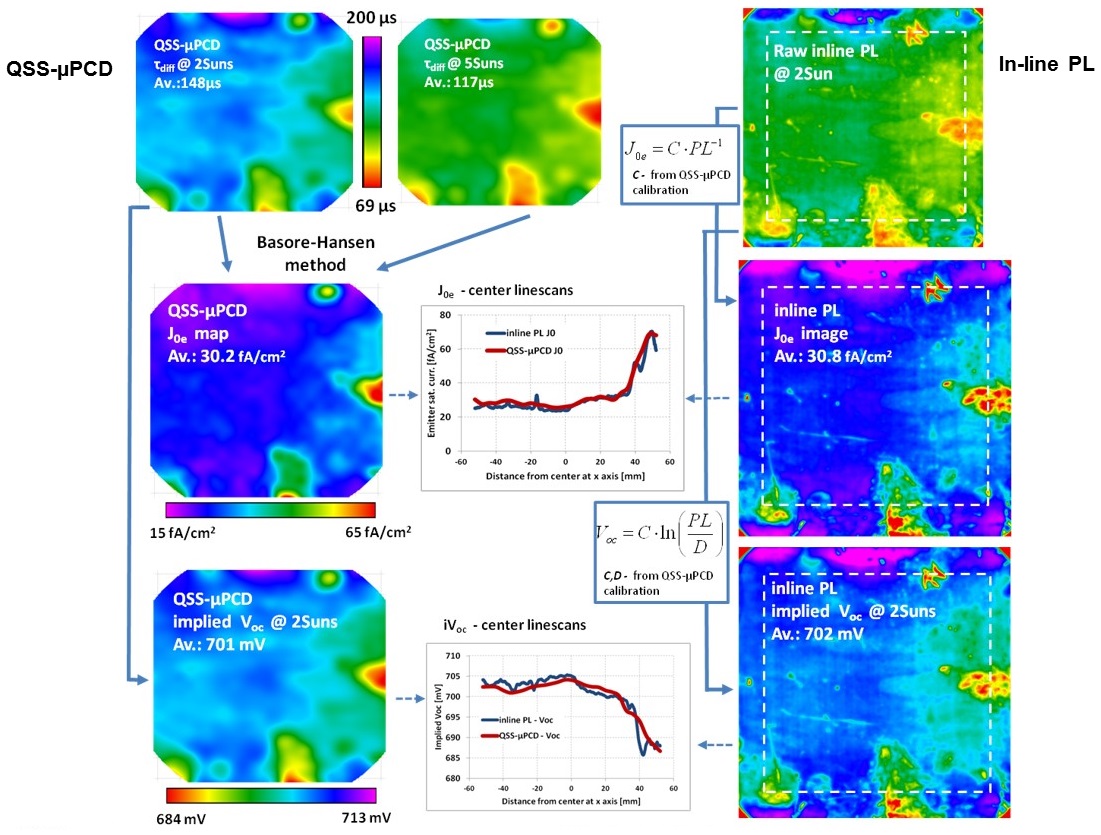

Optional on-the-fly Jo and iVoc mapping

3. Wiring (finished cells):

Shunt

Edge isolation defect

Bad finger

PL IMAGES AT DIFFERENT PROCESSING STAGES:

COMPARISON OF PLI AND LIFETIME FEATURES:

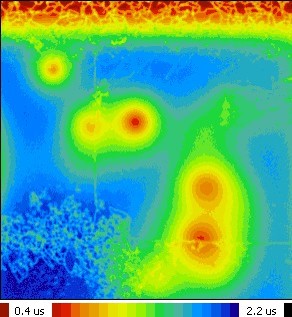

Good correlation between PL and μ-PCD data allows calibration between PL intensity and lifetime:

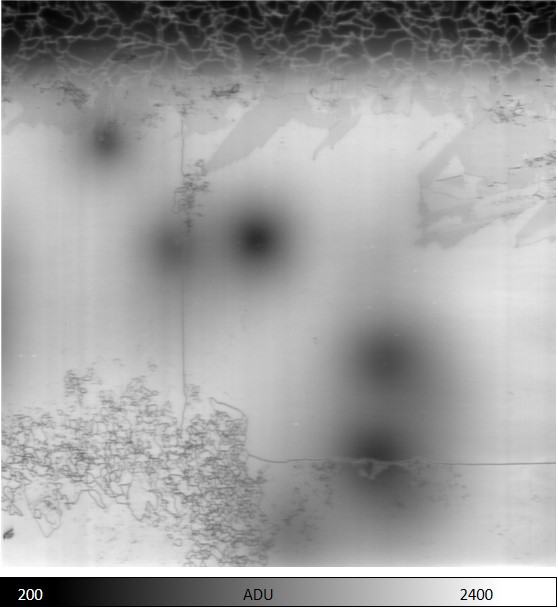

PL image

μ-PCD image

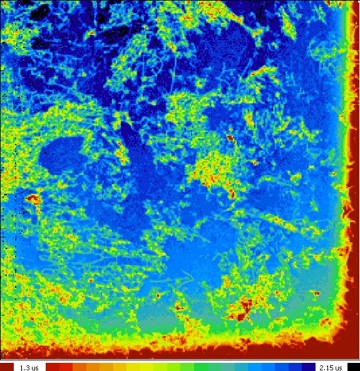

Point-to-point correlation of Multicrystalline wafers with lifetime:

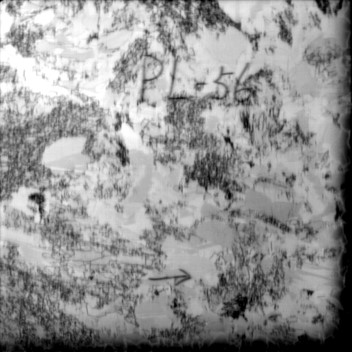

PL image

PL image

μ-PCD image

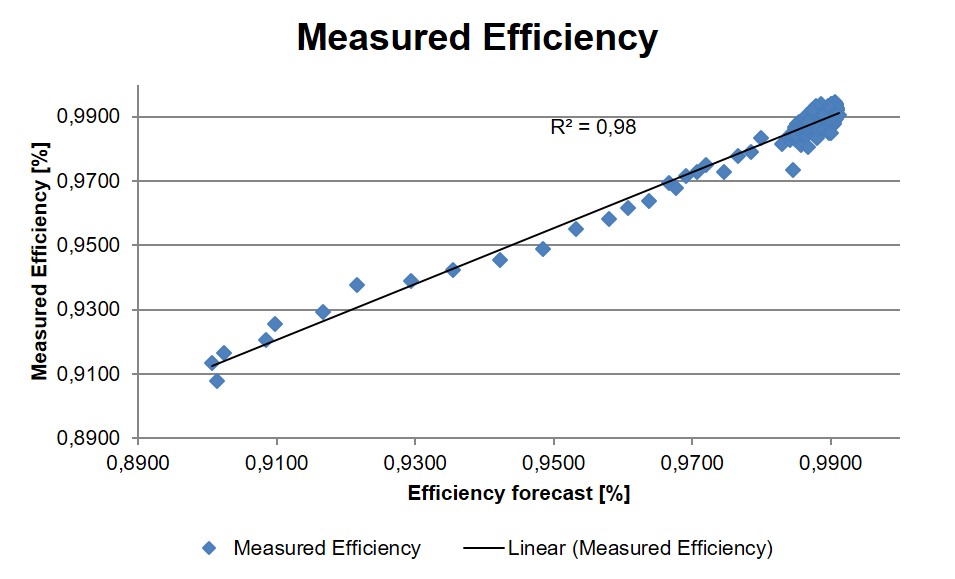

CORRELATION BETWEEN FORECASTED AND MEASURED CELL EFFICIENCY

Semilab’s sorting solution provides good consistency between multicrystalline wafers and efficiency of final cells.

COMPARISON OF J0 AND IMPLIED VOC MAPPING BY QSS µ-PCD

FEATURES

- Reflection side photoluminescence on finished cells, processed and as-cut wafers

- On the fly lifetime map from µ-PCD calibrated PL image

- Applicable for R&D usage

- Quality description by calibrated lifetime map and customizable classification parameters

- Cell efficiency forecast from PL images as-cut multi/monocast wafers (calibration required)

- Measurement capability both on slurry and diamond-cut wafers

Product Line

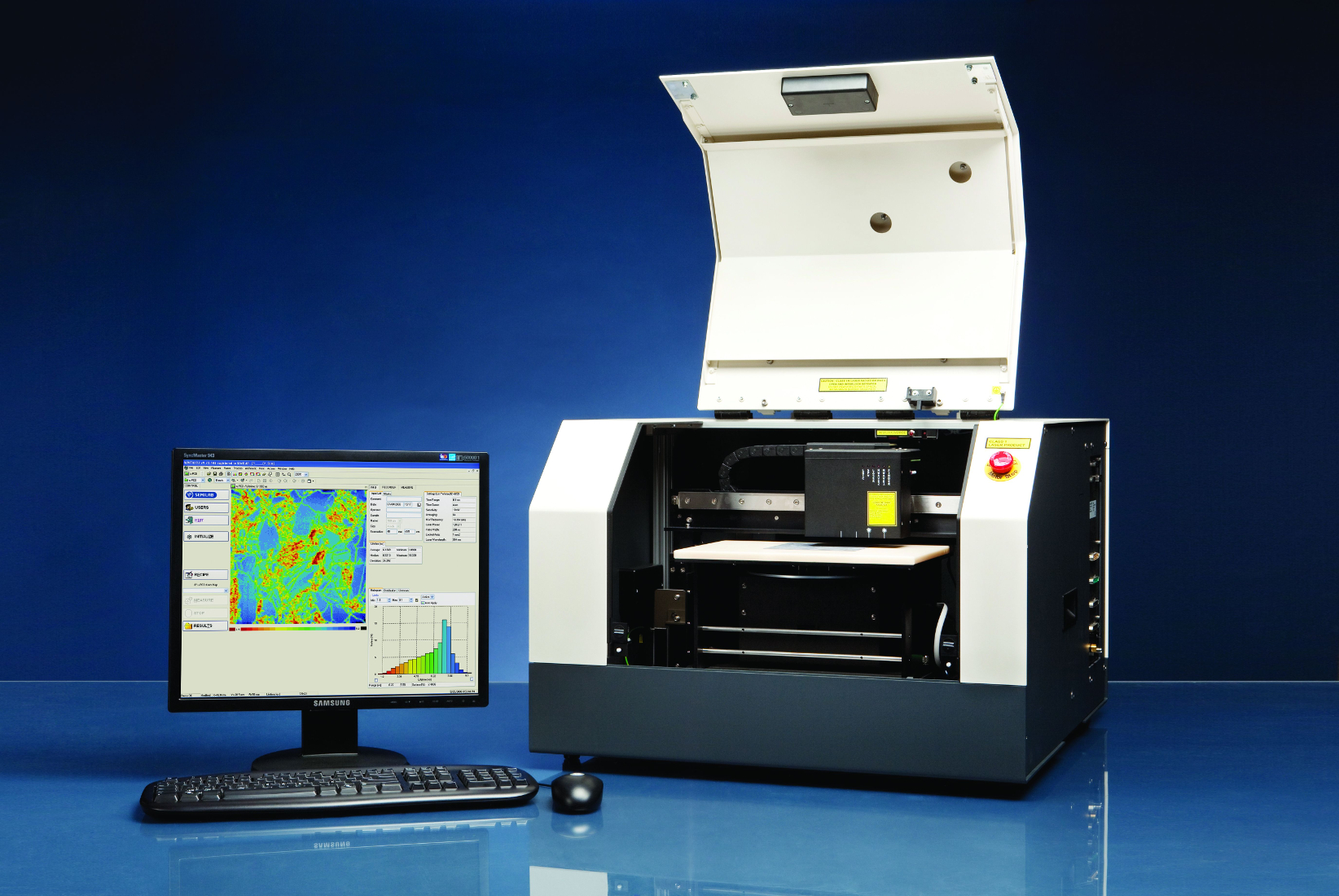

PLI

Photoluminescence tool for wafer and cell inspection is a fast and reliable solution for non-destructive measurement of wafer and cell quality at any stage of processing from as-cut wafers to finished cells.

Provides full control of material quality during the whole production.

Higher quality wafers create higher efficiency cells making the production more cost-efficient.

Products

PLI-1001/A, PLI-1003/A

Photoluminescence tool for wafer and cell inspection

Inline photoluminescence tool is a fast and reliable solution for non-destructive measurement of wafer and cell quality at any stage of processing from as-cut wafers to finished cells.

Provides full control of material quality during the whole production.

Higher quality wafers create higher efficiency cells making the production more cost-efficient.

Features and System specifications:

- Fully automated inline photoluminescence imaging and inspection

- Reflection side photoluminescence on finished cells, processed and as-cut wafers

- On the fly lifetime calibration

- Quality description by calibrated lifetime map and custom classification parameters

- Sample size: PLI-1001/A up to 156 mm

PLI-1003/A up to 162 mm

Types of detectable defects:

PLI-1001, PLI-1003

Material:

- High dislocation density

- Cracks

- High contamination density

- Edge (corner) contaminations

- High vacancy density (for mono wafers)

- Low lifetime

PLI-1001, PLI-1003

Wiring:

- Shunt

- Edge isolation defect

- Bad finger

PLI-1001A, PLI-1003A

Passivation coltrol (double side passivated samples)

- Optional on-the-fly Jo and iVoc mapping