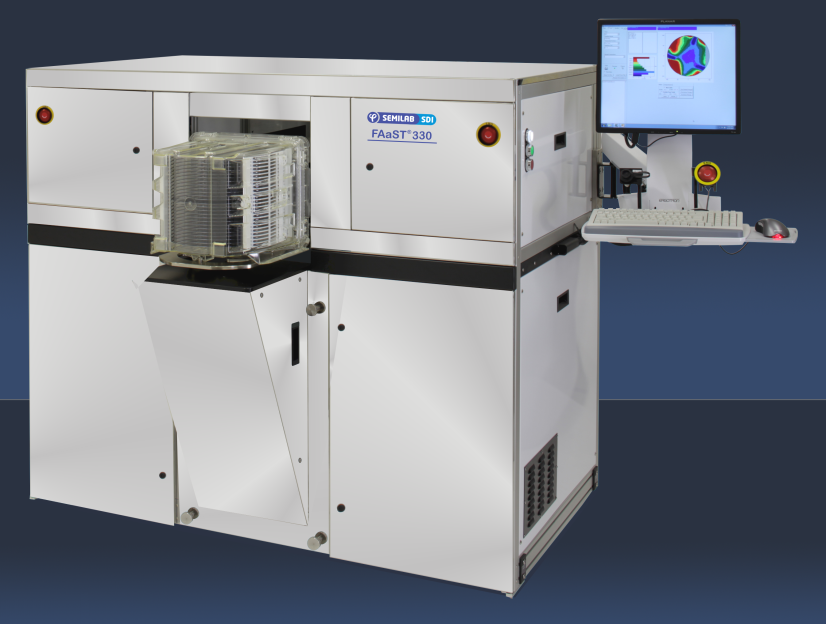

FAaST 330/230 C-V / I-V

FAaST 330/230 C-V / I-V systems apply Semilab SDI’s advanced C-V / I-V measurements based on patented corona-Kelvin methods to provide non-contact imaging of dielectric and interface properties on monitor wafers. These platforms include automated wafer handling that is suitable for the medium to high-volume manufacturing environment. These models feature:

- Automatic robotic wafer handling

- Single open-cassette wafer loading station; with configurable options including SMIF / FOUP Loadport / Versaport

- Full wafer NVD inspection and Plasma Damage Monitoring using Surface Voltage FAST Mapping mode

- Automatic programmable sites or contour mapping of dielectric properties including:

- Dielectric Capacitance (CD) and Thickness (EOT)

- Dielectric Leakage Current (I-V)

- Flatband Voltage (Vfb)

- Interface Trap Density (Dit)

- Interface Trapped Charge (Qit)

- Semiconductor Surface Barrier (Vsb)

- Oxide Total Charge (Qtot)

- Mobile Ionic Charge (Qm), among others

- FAaST software package; including Measurement, Recipe Writing and Data Viewing applications

- Suitable for measurement on: semiconductors (e.g. Si, SiGe, InGaAs, SiC, GaN) with high-k and low-k dielectric films (e.g. SiO2, SiNx, Al2O3, HfO2 ; mixed dielectrics and dielectric film stacks)

- Configurable for 100mmto 300mm wafers, with options available to accommodate multiple wafer sizes and to allow for manual load of smaller wafer diameters

- Line Conditioner with flexible compatibility

- Compatible for configuration with other Semilab SDI FAaST tool measurement technologies

- Additional available options include: Mini-environment, 300mm Semi compliant Automation, Seismic brackets, wafer OCR, RFID, cassette barcode reader, 1000V Vcpd measurement range