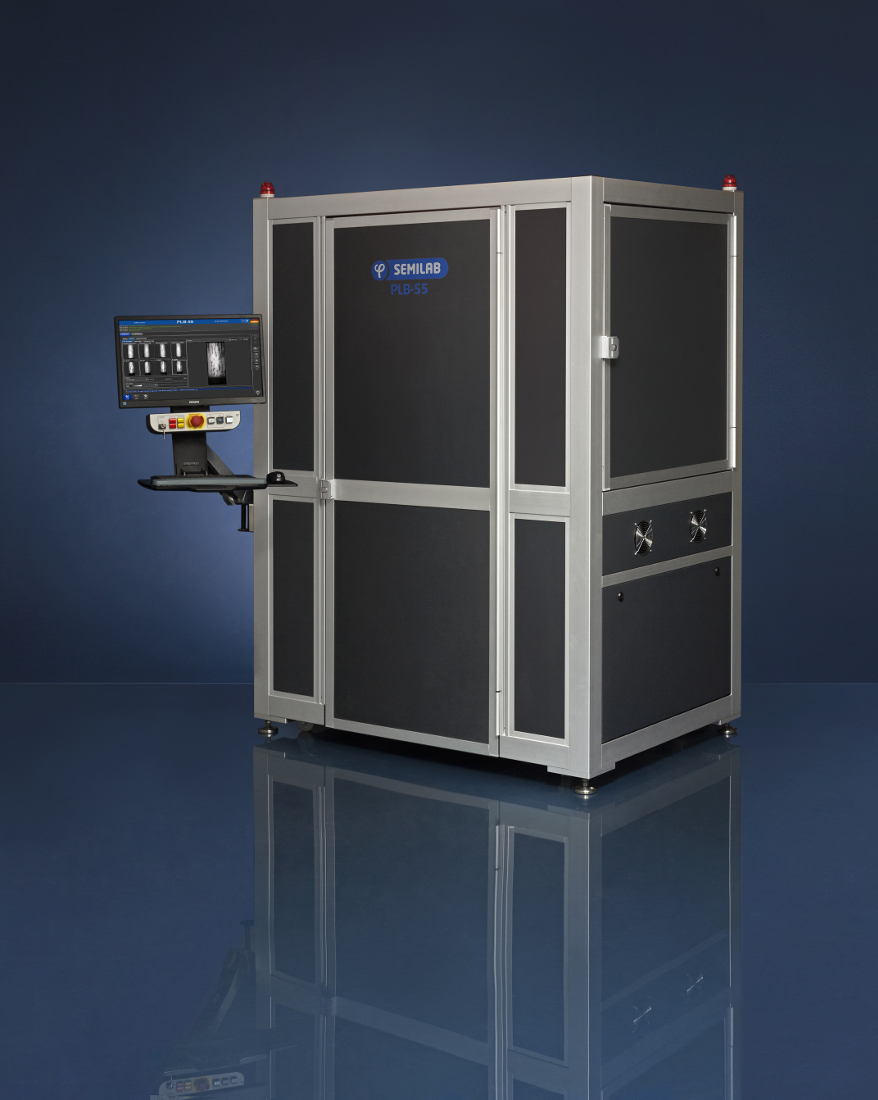

PLB-55 Photoluminescence Silicon Block Imaging System

PLB is fast, non-contact, easy-to-use system to detect defects and impurity concentration in silicon blocks for photovoltaic application.

Features and System specifications:

Ingot Imaging system:

- Photoluminescence lifetime measurement - mapping for all 4 sides

- Max block size: 159×159×500 mm

- Block type: polished or non-polished block

- IR transition based inspection

- Built in integrated μ-PCD lifetime measurement with 1 probe for in-situ calibration - 1 line scan per side and lifetime calibration of the entire PL image.

- Block size determination with built Omron optical sensors

- Built in eddy head for resistivity measurement 1 line scan per side

- Built in P/N tester for conductivity type determination 1 line scan per side.

- Weight measurement (Max. 50 kg, 20 g accuracy)

Additional Measurements:

- Resistivity measurement with eddy head

- Lifetime measurement with μ-PCD head

- Temperature measurement with pyro sensor

- PN conductivity type measurement

- Block weight measurement

- Block size measurement

- Block angle measurement

Software evaluation:

- Calculated lifetime map

- Determination of the cutting line based on lifetime

- Determination of the cutting line based on resistivity

- Defect area percentage

- Colored images

- Export data to Excel

Options:

- High resolution images (transmission, PL)

- Fully automated robot support

- Block marker and printing

- G-code for CNC machines

- MES

- Slug measurement for R&D

- Language options: English, Chinese, Hungarian, for other, please contact us